Large logistics centres use 1D and 2D codes to identify cardboard packaging, whereby high contrast is essential for reliable code reading.

Codes require even illumination at all times, regardless of the working distance. To achieve this, a flat dome light is positioned on the side of the conveyor belt, with a code scanner located in the central opening. The flat dome provides homogeneous illumination across the entire field of view, ensuring that codes on the shipping boxes are always readable with maximum accuracy.

Challenges

- High contrast needed for accuracy, requiring outstanding homogeneity

- Variety in parcel sizes and the exact position of codes on the packaging

- Varied distances between codes and the code reader

Solution

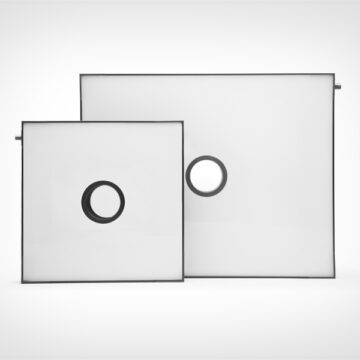

- HPFDOME: powerful illumination preserving the highest brightness and uniformity balance

- Narrow 4mm thin borders

- High uniformity: homogeneous illumination for accurate readings

- Easy integration due to standard M12 5-pin connector

Want to achieve homogeneity in logistics applications? Download our full Tech Note!

In logistics, illumination is usually mounted on a gantry alongside a camera to read codes and labels. This step is crucial for inbound and outbound processing, where boxes are often in motion at very high speeds. With continuous growth in the e-commerce sector, lines must be future-proofed to keep up with the accelerating pace of parcels. These vision systems demand exceptional homogeneity and high brightness to reduce the effects of ambient light and motion blur. Request a copy of our tech note for more information!