TPL Vision has worked with MV Center (Poland, https://www.mv-center.com) on a line scan application dedicated to inspecting TV components for one of the largest manufacturers in Poland.

MV Center provides the design, construction, and implementation of machine vision systems, based on intelligent cameras and efficient embedded systems. Their solutions ensure 100% quality control of products, enabling users to increase the efficiency of production processes.

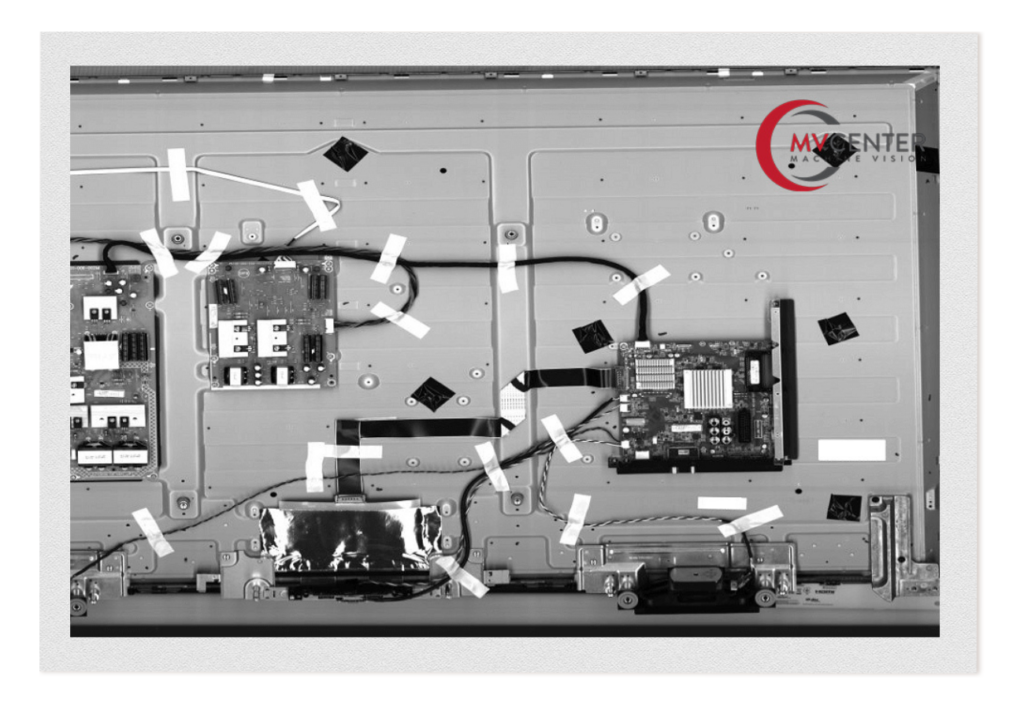

MV Center’s line scan application was designed to inspect TV components on the back of TVs before they get covered up. Examples of components being inspected include checking for the presence of mounting screws and examining the position of tapes for fastening cables.

Challenges

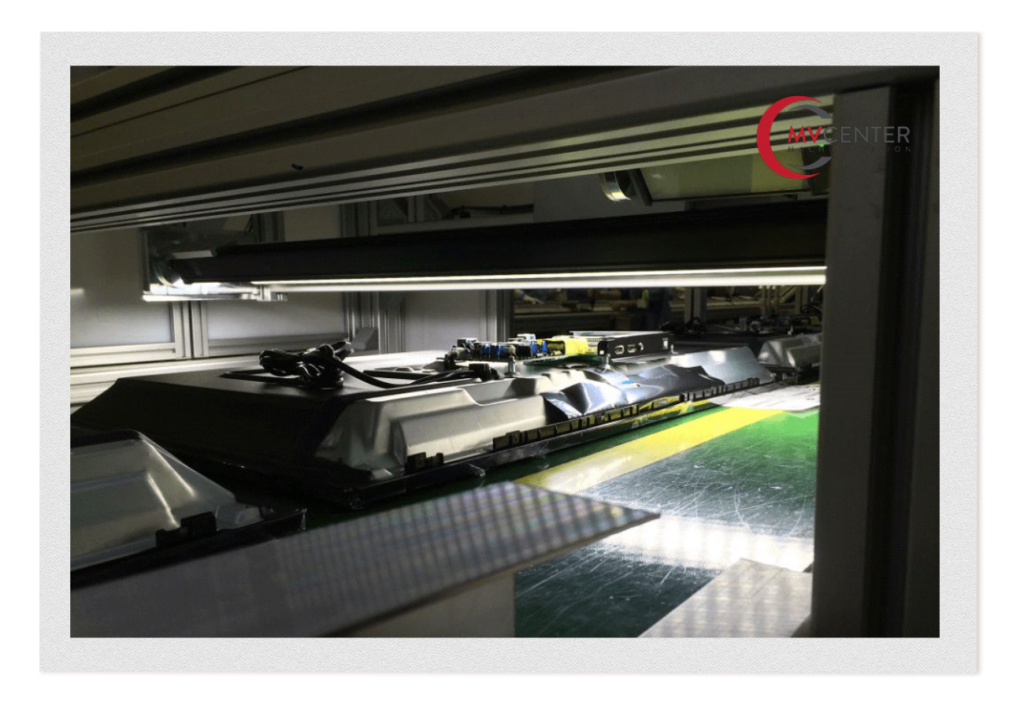

With the conveyor belt moving at a high speed (around 0,1m/s on average – it only takes 20 seconds to inspect a TV!), MV Center needed bright, but long-lasting illumination. All line scan applications must be supported with high brightness lighting to avoid motion blur.

To make this happen, they opted for a powerful bar light able to provide homogenous results, even on a field of view as large as 1,2 metres.

Solution

The highly powerful EBAR+ in white was selected for this project. The selected size of this bar light (1250 mm) was ideal to cover the whole field of view, up to the edges of the conveyor belt. Although MV Centre was considering getting two bar lights installed, due to the large size of the EBAR+, having only one light was sufficient.

Moreover, because the EBAR+ is equipped with elliptical lenses, this allowed MV Center to build up the light very close to the field of view, and still maintain an intense, homogenous line.

What is a line scan installation?

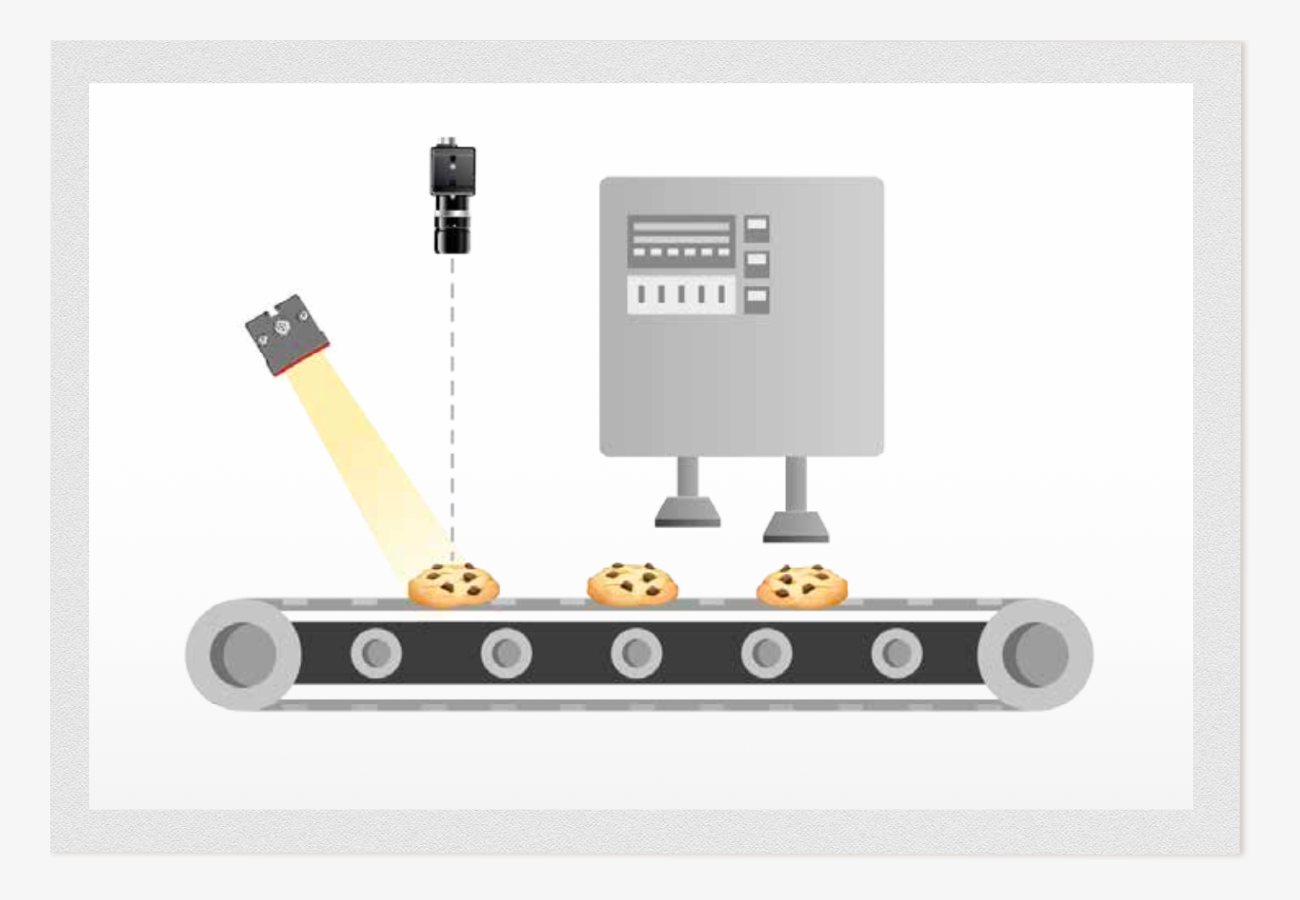

2D machine vision systems use cameras to capture the image of an object using a two-dimensional map of reflected intensity. In line scan applications, pixels are aligned in a single row along the width of the field of view, building up a two-dimensional image based on the motion of the object being imaged. Line scan imaging is a cost-effective option of capturing fast moving objects due to the motion blur being reduced through the combination of short exposure time and intense illumination.

To create a 2D image, the object being inspected is moved perpendicularly past the line of pixels in the image sensor. The camera captures images continuously, creating a full image of the object being inspected.

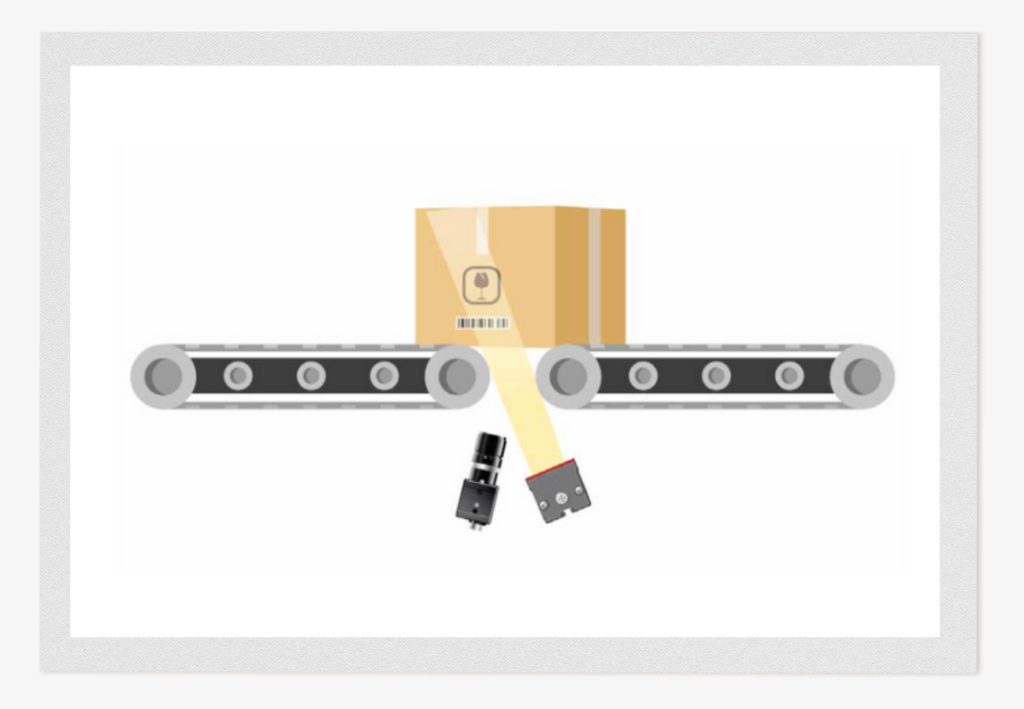

Line scan applications remain a cost-effective inspection method while excelling across various industries such as pick and place, logistics, and code reading. Line scan systems are perfect for high-speed applications and are known as a trustworthy solution for detecting defects or imperfections on objects.

However, they must always be equipped with high brightness illumination capable of providing uniformity and stability across the whole field of view.

Line scan applications capture fast-moving products using a very short exposure time and a bright and concentrated source of illumination.

Line scan is also often preferred when the available space is limited, such as reading codes on the underside of boxes on a conveyor belt.