Artificial Intelligence applications are the cutting edge of the Software element in Machine Vision systems. However, for the complicated software to work to the highest efficiency the image must contain a high uniformity on the parts being inspected. The ideal lighting type must create homogeneity across all images, for this the user needs:

1. The right type of light for the application:

- Darkfield Illumination

- Backlight

- Bright field Illumination

- Dome Lighting

2. High brightness – to kill any variation caused by ambient light.

3. Full coverage of the FOV with the homogeneous lighting configuration of choice.

Fortunately, the Modular Bar, when combined with the Angle Changers gives the user both excellent uniformity and flexibility to operate in many configurations (Except for backlighting – see TPL Vision’s backlight products here).

The flexibility side of the Modular Bar means the user can play around with different output to suit the configuration they need, whether that is darkfield lighting, brightfield or dome lighting, there are many possibilities with the Modular Bar.

High brightness is inherent in the Modular Bar, it has OverDrive embedded which means the product is more intense for the first 30ms of a strobe signal. OverDrive/Autostrobe is particularly useful for applications that are critical to the application, such as high-speed ones. For applications that do not require or cannot be in strobe mode the light is a very high intensity in continuous working, around 4000 Lux at 2m working distance. Furthermore, if the intensity of standard working mode is still too high, perhaps for operators in the environment, the light can be dimmed down to 30% of the continuous mode brightness.

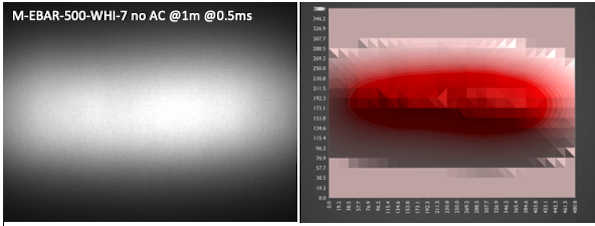

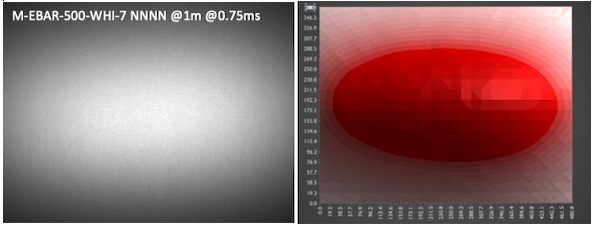

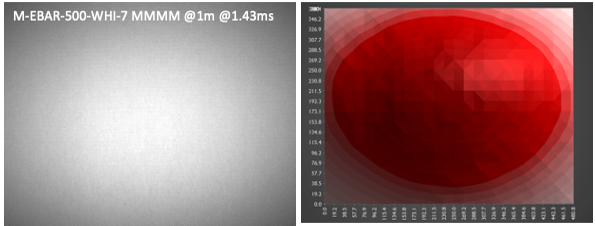

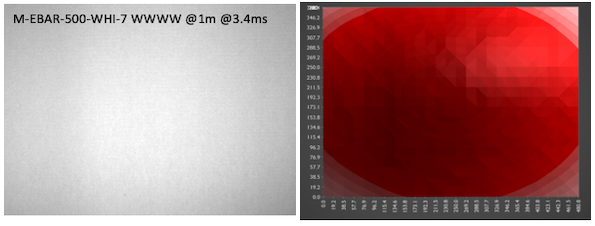

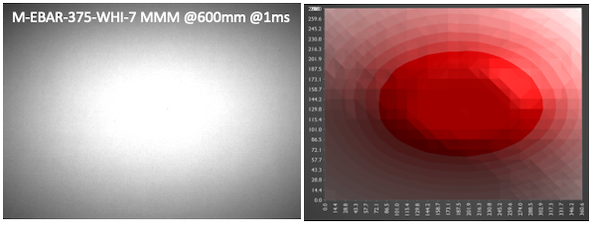

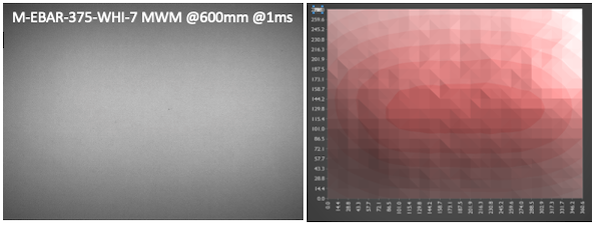

As shown in the images of the varying Angle Changer outputs below, the homogeneity across the surface can be varied and controlled with the Angle Changers. The homogeneity can be further enhanced using the Curve Effect (patent pending). One of the great features of the Modular Bar is the smooth Gaussian light distribution across the surface. Combining this feature with the use of Angle Changers gives the user the ability to find the configuration that perfectly suits the application.

Curve Effect Enabled by changing the middle diffuser when using one bar. It can also be created by using a variation of diffusers over multiple products for covering large areas homogeneously. Note how the hotspot is significantly reduced over the two images by simply changing the middle diffuser.

Scortex, a company developing an AI-powered quality inspection solution, with a unique multi-cameras and multi-defects capable offer, successfully solves critical quality problems for their customers. Deep Learning is becoming a more and more trusted solution, especially when conventional rule-based machine vision devices fail. Furthermore, it has also been introduced as an ‘easy-to-set-up-and-use’ technology.

However, as Scortex machine vision expert Yann Chéné advocates, “AI-powered vision systems need a stable illumination environment to operate truthfully. External illuminations help to create the right contrast and contribute in achieving a robust inspection. We have selected the TPL Vision Modular bar concept with Angle Changers as a go-to illumination solution for our latest deployment. During our use case validation analysis, we demonstrate that light is bright enough, very smooth and uniform, and we can change the diffusion byadopting various available accessories.”