NOTE: What is a large Field of View (FoV)? A large area does not have an exact definition, a large FoV for TPL Vision would be a FoV width >500mm and a working distance (WD) >500mm. However, to others this definition may vary and the illumination principles which are outlined in this application study can also be applied for all sizes of FoV.

What challenges are there for illuminating large FoV’s?

In all vision applications there are two key components you need: 1. Brightness and 2. Homogeneity. The larger the field of view the harder it becomes to achieve these two elements. It is well known that the intensity or brightness of light is strongly correlated with the working distance, this relationship is called the ‘inverse square law of light’, this means that the intensity of light is inversely proportional to the square of the distance. So, as you create a larger Field of View and the larger working distance, to see this field of view you need more intense lights to ensure stability in your vision results.

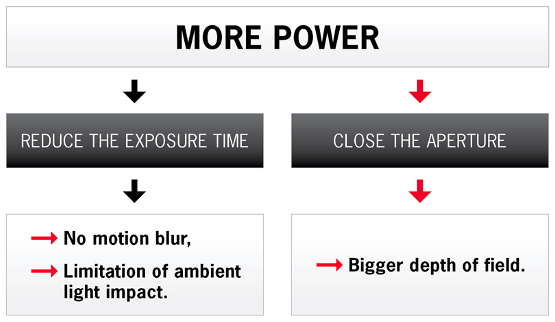

Brightness is critical for all vision applications. You must have high intensity of lighting to reduce the impact of ambient light, reduce motion blur and have an increased depth of field.

The latter is especially critical on large Fields of view because the larger the field of view, the larger difference between the working distance from the centre of the field to the camera and the working distance from the edge of the field of view to the camera.

We now understand the role ‘high brightness’ plays in Vision applications and particularly for large fields of view.

So where does homogeneity come in? Homogeneity is all about creating image stability to make your camera’s machine vision software function properly. The more homogeneous or uniform your inspected components appear on your field of view, the more stable your vision system will be. If you are looking at your field of view to guide a robot to pick up some biscuits, it will certainly be more difficult if one biscuit is illuminated well and one is not.

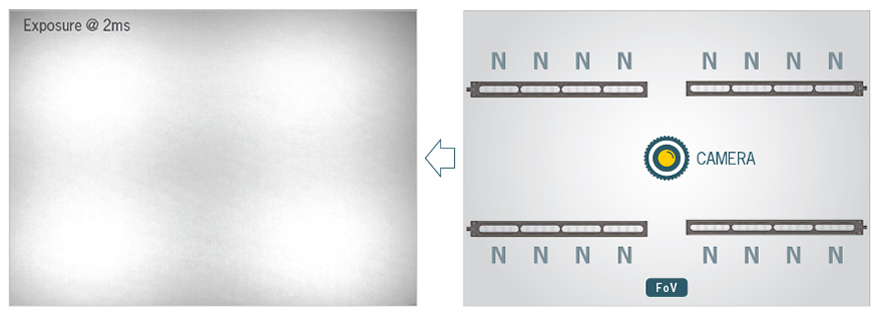

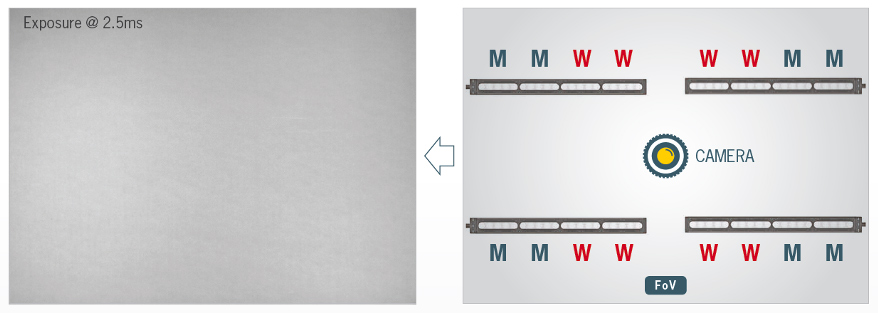

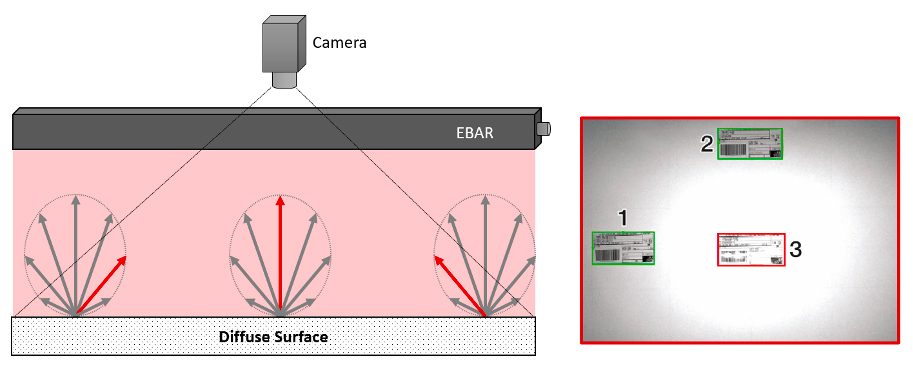

On a large field of view the challenge comes because of parallax and the way that illumination is distributed on various surfaces. Often when lighting is illuminated on a large area there will be a higher intensity in the light in the centre of the FoV, this is because the light reflected off the surface is stronger in the camera’s central axis than it is in other areas of the FoV. It may appear something like the images that are shown to the left, where the length of the red arrows represents the relative intensity of light reaching the camera.

To illuminate large FoVs you need lighting that is dedicated to assist you in achieving the best balance between brightness and homogeneity. TPL Vision’s Modular Bar is designed with exceptional lighting homogeneity, and along with the Angle Changers it is possible for you to illuminate FoVs of all sizes.

- To create the best brightness, the Modular Bar has integrated OverDrive functionality, meaning that in strobe mode the light can achieve up to 87,000 lux at 500mm working distance. If you cannot use the strobe functionality, perhaps due to operator safety and comfort, the Modular Bar has extremely high brightness in continuous working. TPL Vision have found that the continuous working level of Modular Bar brightness is suitable for 90% of all machine vision applications.

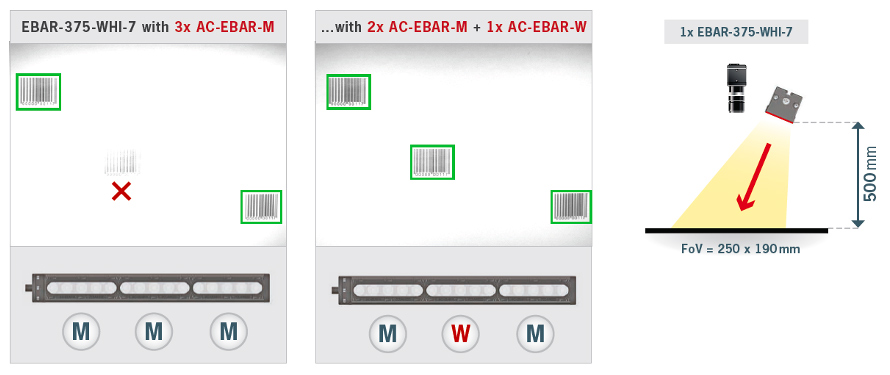

- To create the best homogeneity, the traditional method of using a light that is double the size of the field of view is now out-dated. Machine designers and integrators often have much less space to work with for vision systems so using very large lights is not always feasible or economical. By combining the Modular Bar with the Angle Changers, it is possible to create the ‘Curve Effect’. This is a patented system by TPL Vision that allows the user to improve the surface homogeneity to achieve the best balance between brightness and homogeneity. The ‘Curve Effect’ is created by increasing the angle, and applying some diffusion to the illumination in the centre of the FoV. See the following examples: