In the automotive industry, automated tyre inspection ensures compliance with safety standards and prevents defects. Enabling accurate and fast defect detection, this vision system inspects hundreds of tyres per hour to eliminate the chances of human error, facilitating a much faster, streamlined inspection process. This ensures improved tyre safety and performance, which helps to prevent accidents.

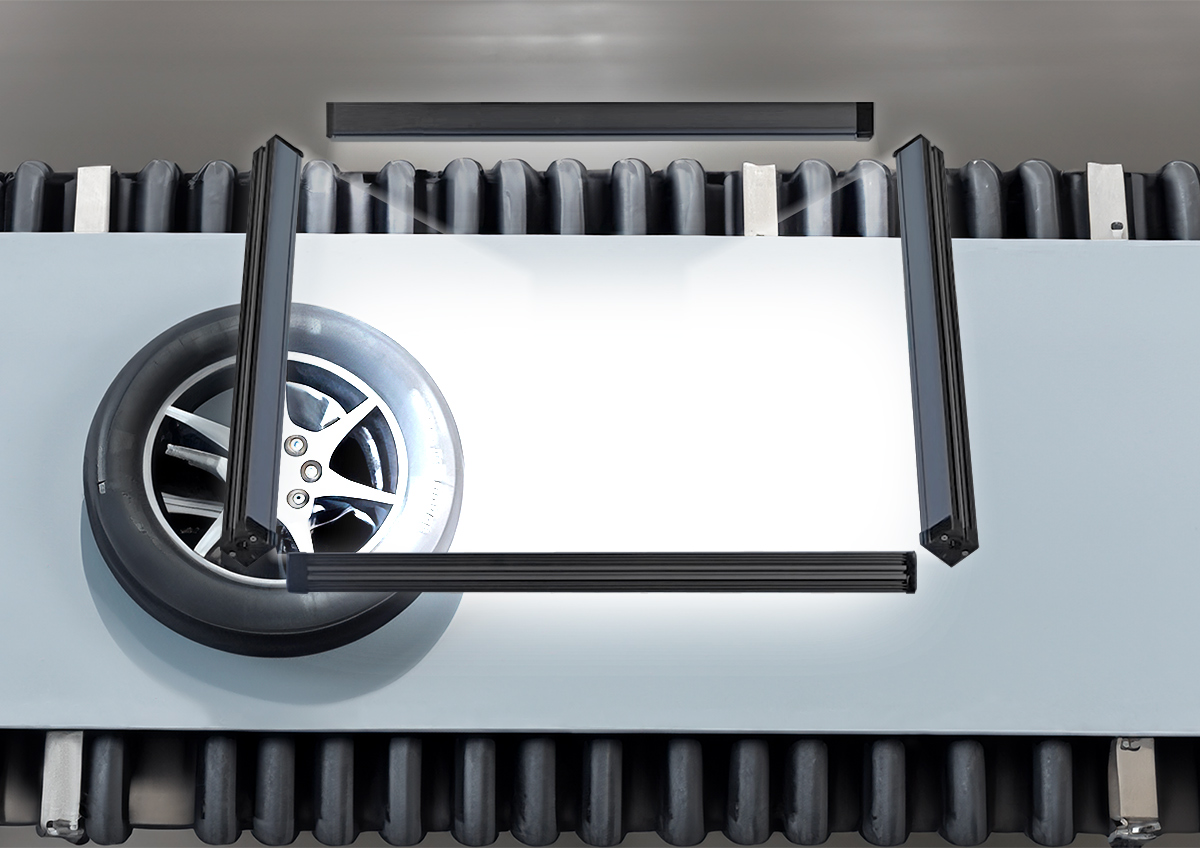

Using a smart camera and powerful bar lights, the top and bottom of tyres are inspected simultaneously. The system checks for surface defects, tread pattern, DOT codes and branding elements, as well as the overall integrity of tyres.

Challenges

- Lack of homogeneous lighting: Due to the complex geometry of tyre treads, powerful and consistent illumination are key. Different tyre models have varying geometries and surface textures, which can affect how light interacts with the surface. Designed to be integrated into production lines, consistent lighting for real-time feedback is essential to ensure only high-quality tyres proceed to the following stages.

- Multiple inspection points: the tyres are imaged from the top and bottom simultaneously to maximise production speed. It is crucial that the cameras capture accurate, blur-and distortion-free images to effectively identify any defects.

Solution

- Powerful illumination with OverDrive: OverDrive EBAR+ bar lights allows the system to achieve increased light intensity for a short amount of time. The use of OverDrive lights ensures that even at high production speeds, the lighting allows for accurate and reliable defect detection without sacrificing inspection speed.

- Uniform lighting: The chosen bar lights are adjustable and can be configured to accommodate the varying sizes, shapes, and surface characteristics of different tyre models. his uniform illumination enables the accurate identification of defects, as well as the correct reading of DOT and DOM codes using artificial intelligence, ensuring complete traceability.

Results:

The Future of Automotive Production

Machine vision plays a pivotal role in the automotive industry, far beyond just tyre inspection. These systems can spot tiny flaws in paint or components with incredible accuracy, ensuring high-quality finishes and reliable parts. Often paired with robotics, machine vision boosts efficiency and precision in the production line. For a deeper look into how machine vision is transforming the future of vehicle manufacturing, check out the rest of our case studies!