Line scan applications always involve moving objects, and the camera creates a continuous image through a single line of pixels along the width of the FoV.

This create a continuous image that is useful for web applications, some pick and place applications, food and beverage quality inspection and logistics applications, amongst many other applications.

To create this continuous image the camera operates at an extremely high frequency, which requires the light to operate in continuous working, with extremely high homogeneity (along the pixel line) and the intensity of the light is critical.

The Modular Bar, along with the Angle Changers, is an excellent tool for line scan applications that are not at the extreme of high-end line scan applications. Sometimes the most common reason for a line scan application is the availability of space. The Modular Bar can be used for these applications, which often include pick and place, and other conveyor belt applications. See below for some examples:

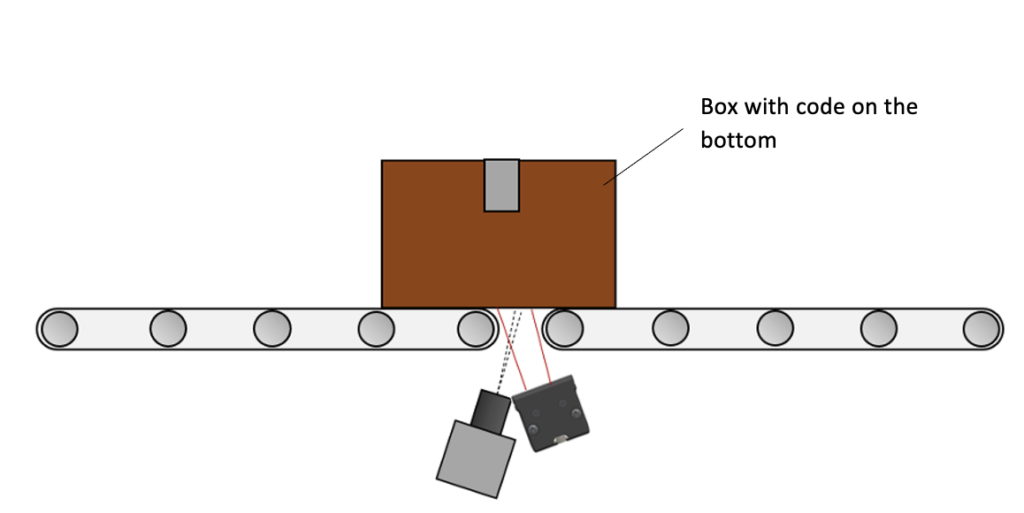

1. Logistics Example of Line Scan Application using the Modular Bar

Confined space: reading codes on the underside of boxes by placing a line scan camera and a Modular Bar with AC-EBAR-L in the gap between two conveyor belts

Minimum suggested working distance from light to target = 100mm

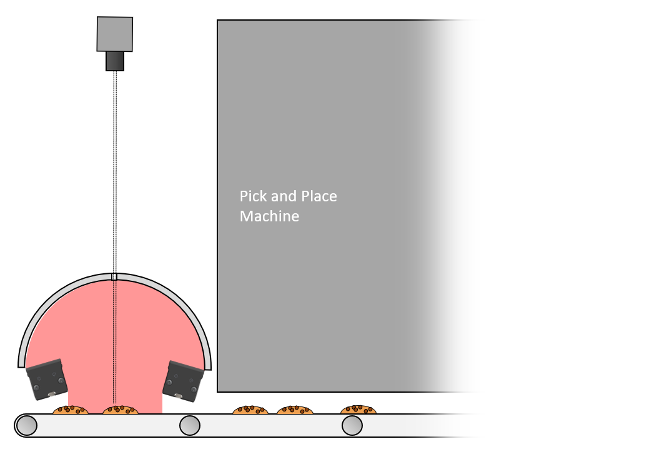

2. Dome Lighting Line Scan application for Pick and Place

For pick and place Applications, sometimes the picking/robotics part of the machine takes up so much space that the vision system must be a line scan one. You can do this with TPL Vision’s lights in two ways.

This first example shows how a dome can be created for slow line scan applications that require a highly homogeneous result over a complicated surface, such as biscuits.

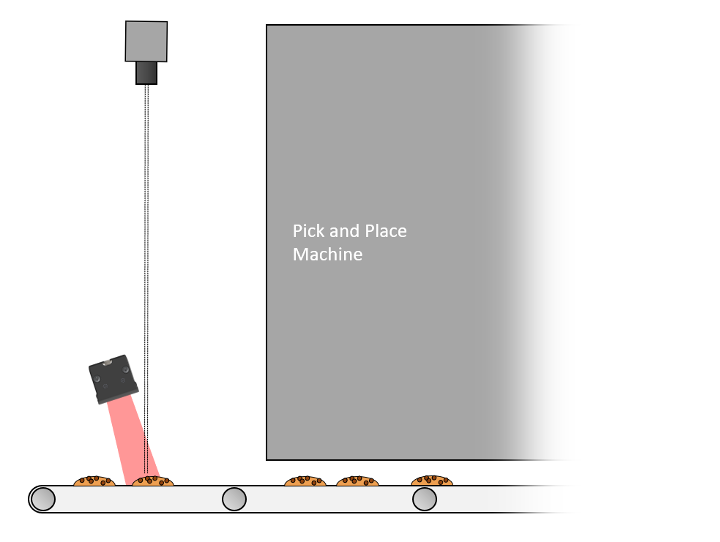

3. Line scan Lighting for Pick and Place

Similarly to option 2. The Modular Bar with Angle Changers (AC-EBAR-L) can enable direct lighting line scan illumination to reduce the overall foot print of machine vision systems on pick and place lines.

Minimum suggested working distance from light to target = 100mm