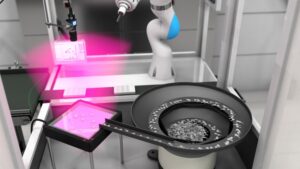

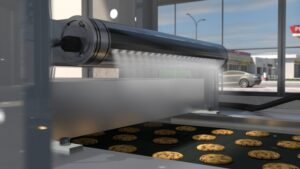

IP69K bar light used in pick-and-place application in the food industry

In this pick-and-place application, high-speed conveyor belts carry freshly baked cookies to be expertly packaged. The vision system uses high brightness IP69K-rated bar lights to accurately determine the cookies’ location and orientation.