Undergoing continuous transformation due to technical advancements, the landscape of the healthcare industry is constantly evolving. Plastics, through innovative applications, have evolved and found their way into various realms of medical devices and equipment, spanning from biocompatible plastic implants to diagnostic tools and robust surgical instruments. The surge in affordable medical tools, new manufacturing methods and the use of automated inspection systems are all contributing to the growth of this sector within the medical industry.

Fisher Smith Ltd. (https://fishersmith.co.uk/) was tasked with the challenge of designing a custom vision system for the 360° inspection a plastic surgical tool. Due to the company’s experience in comprehensive machine vision solutions using high-quality components, they successfully developed a system capable of conducting inspections that meet the rigorous standards of the medical industry.

CHALLENGES

- No room for errors

Quality control is a crucial step to ensure the safety of the instrument. The manufacturer had to implement controlled processes to achieve consistent quality and precision while maintaining the speed of production. The instruments must all undergo strict sterilisation validation to assess their safety. - The strictest quality control regulations

Regulatory bodies, such as the European Medicines Agency (EMA) and the U.S. Food and Drug Administration (FDA), provide strict guidelines for the manufacturing and testing of plastic surgical instruments. - Moving parts with complex shapes

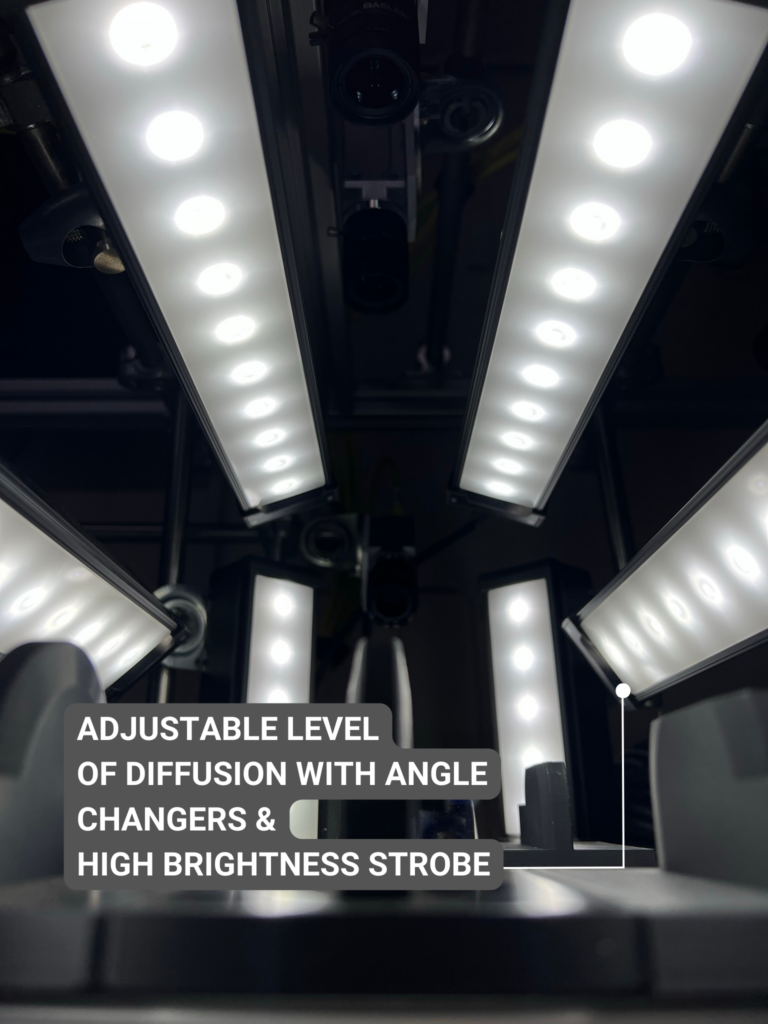

Parts are moving on a conveyor belt at a fast speed and require a very detailed visual inspection. Due to their complex geometry and the speed of movement, the system required a high-brightness lighting setup delivering maximum intensity while preserving homogeneity across the FoV.

SOLUTION

- A powerful setup for maximum accuracy

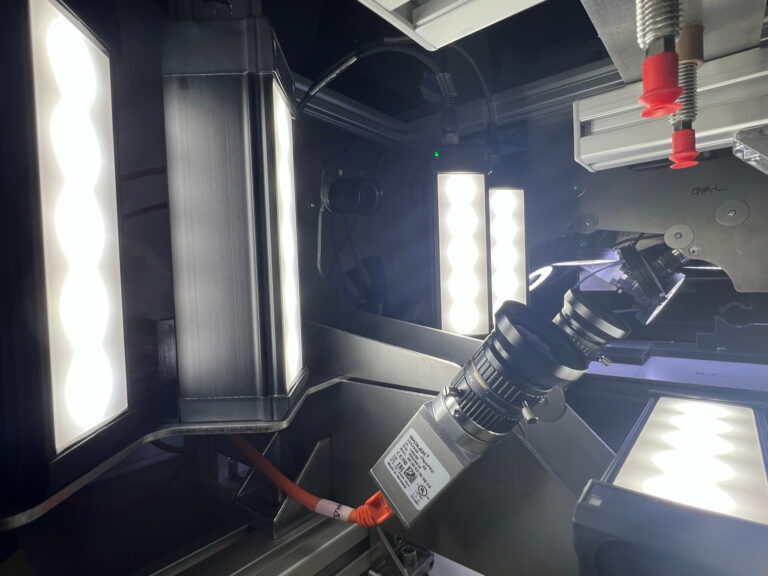

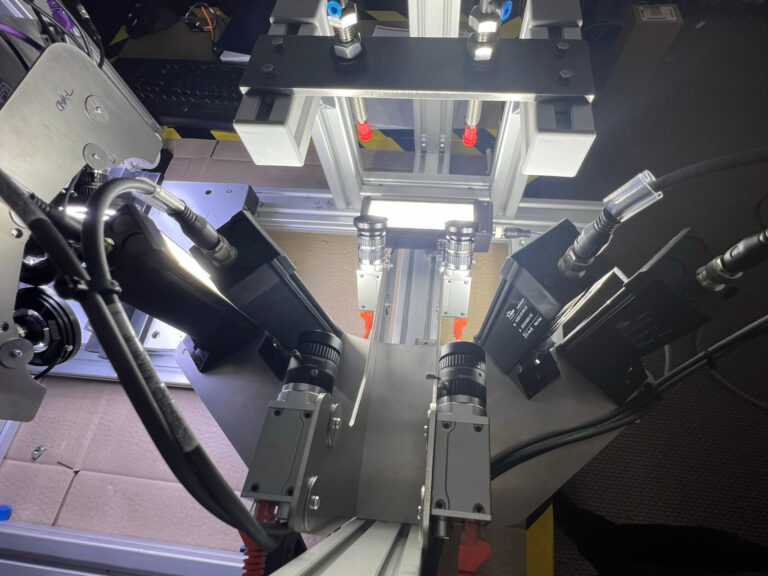

The system is using 25 cameras to capture the object from multiple angles, allowing for a detailed inspection. The uniformity of illumination comprising of the arrangement of 8 Modular M-EBAR bar lights around the scene ensures that no shadows are seen, allowing even the smallest defects to be captured.The powerful lighting minimises disturbances that come from the environment and allows a larger Depth of Field to be captured, which means a broader range of distances can remain in focus during inspection.

- Flexible Illumination

The Modular Bar light provides flexibility and the option to future-proof the lighting system. The bar lights’ beam angle can easily be adjusted with Angle Changers to achieve different lighting outputs from direct to highly diffuse illumination.The M-EBAR also comes with strobe mode, capable of delivering up to 4x times higher brightness output. This allows for the option of easily achieving even greater efficiency and higher speeds in the future, without sacrificing a high level of inspection detail.

- Advanced Deep Learning

By harnessing Artificial Intelligence technology, the system is capable of detecting deviations from anticipated standards that would be impossible for human inspectors to spot. Through the utilisation of advanced Deep Learning, it can provide highly precise outcomes, thereby enhancing productivity and ensuring compliance with regulations.