DISCOVER THE POWER OF BAR LIGHTING

Bar lights, also called line lights, offer versatile bright field, dark field, low angle or even dome illumination. Achieving optimal object imaging requires careful consideration of installation position, light quantity, and angle of incidence. Bar lighting serves as an effective solution for applications in machine vision, industrial automation, robotics, and identification.

Lighting Techniques using Bar Lights

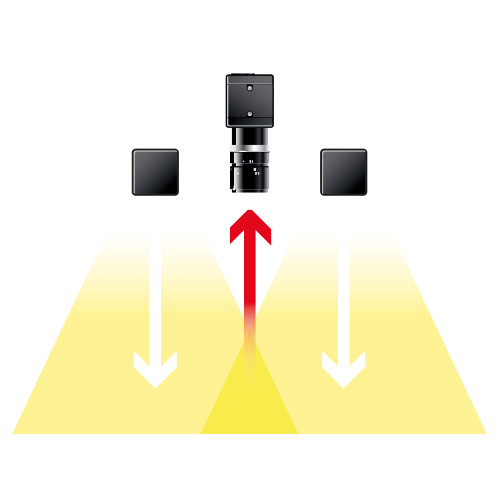

Bright field

Using bar lights as bright field illumination ensures objects are well-lit from the direction of the camera’s perspective. This lighting technique is ideal for examining the overall structure and features of non-reflective objects or surfaces without emphasising specific details or irregularities.

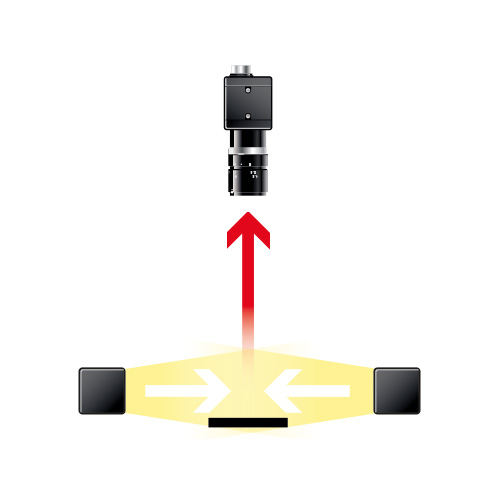

Dark field

Dark field lighting is created by placing the lights with an incident angle between 80° and 90°. This results in the object’s surface appearing as a dark background, while any irregularities or imperfections scatter the light and appear as bright features.

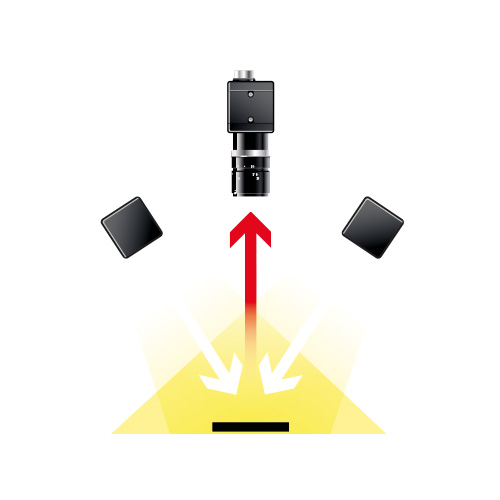

Low angle

Low angle lighting uses bar lights to cast light onto an object at a shallow angle. This technique is employed to accentuate surface texture and reveal fine details, such as scratches and defects in surface inspection and material analysis.

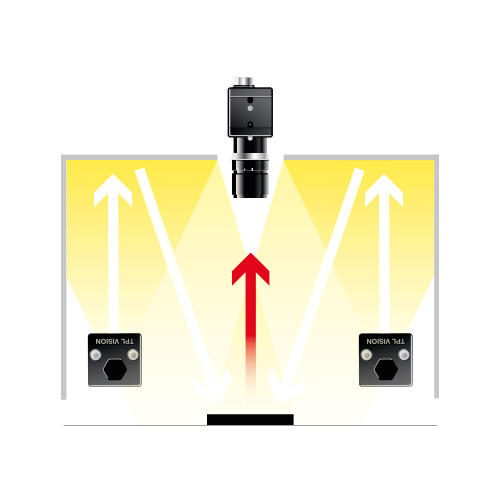

Dome lighting

Dome lighting can be created by placing bar lights facing upwards to illuminate a matte white enclosure. With the camera looking down between the lights, this creates an even and homogeneous illumination that can assist in controlling complex, uneven and shiny surfaces.

Applications

Robotics Applications

In robotics applications across industries, bar lights for robotics offer consistent and focused illumination, reducing shadows and glare while optimising image quality. This, in turn, empowers robots to efficiently identify and manipulate objects, ensuring seamless automation processes.

Material Handling and Sorting

Efficient material handling and sorting require robots to accurately identify and manipulate objects. LED bar lights enable the vision system to discern objects’ shape, colour, and position with exceptional precision, making tasks like bin picking or conveyor sorting highly efficient.

Read more in our case study in which a robot-guided vision system was upgraded with high-brightness bar lights to improve the effectiveness of the system.

Quality Control and Inspection

In manufacturing, robots equipped with vision systems often perform quality control and inspection tasks. Bright bar lights enhance the system’s ability to spot defects, inconsistencies, or imperfections on products, contributing to higher quality standards.

Logistics Applications

Code Reading in Logistics

Illumination for logistics applications is typically placed on a gantry along side a camera set up to read codes and labels on all surfaces of a box. The boxes are usually moving at very fast speeds. Due to the continuing growth in the e-commerce sector, these applications need to be future-proofed to keep up with the ever-accelerating speed of the parcels.

How can this be achieved using bar lights?

- Powerful bar lights can help to reduce the effects of ambient lighting and motion blur for large fields of view.

- Brightness isn’t everything: homogeneity is also needed to ensure parcels of varying sizes and codes in different locations can all get scanned accurately.

How to control the intensity of bar lights?

To get the best balance of both brightness and homogeneity for logistics, the intensity of the light can be controlled using Angle Changers. Angle Changers are durable micro-optic diffusers that clip onto the front of our bar lights. On bar lights of 375mm or longer, the intensity of light can be reduced in the centre by placing a wider Angle Changer in the middle (this is called the Curve Effect). Read more about this technique here.

Artificial Intelligence Applications

Artificial Intelligence (AI) applications represent the forefront of the software component within Machine Vision systems. However, for even the most advanced algorithm to operate at peak efficiency, the images must be uniformly illuminated.

Bar lighting is often used in AI applications to provide consistent and controlled illumination for imaging and data acquisition in applications such as:

- Object Detection

- Quality Inspection

- Automated Manufacturing

- …and many more.

Illumination requirements for AI

- Contrast: AI and Deep Learning models rely heavily on the quality of input data, and well-lit images with minimal noise and good contrast enable these models to make the most accurate predictions and classifications.

- Consistency: Uniform lighting helps the model learn underlying patterns rather than false errors caused by lighting changes.

- Reduced noise: adequate lighting can help eliminate noise in images, such as shadows, reflections, or glare, which can cause interference. Diffuse bar lights and the proper positioning of illumination can help minimise these issues.

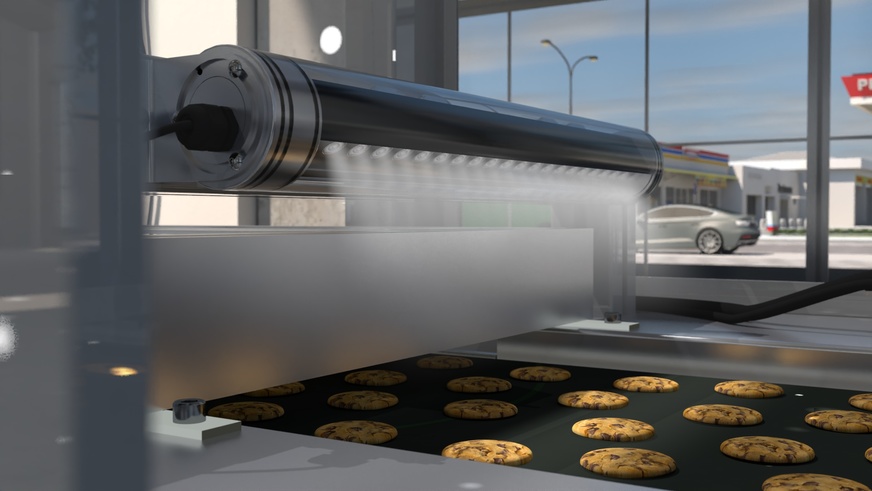

Washdown Applications

Withstand harsh environments where equipment is regularly subjected to water, chemicals, and cleaning processes. Washdown bar lights typically have high IP ratings to withstand water and dust exposure. Application areas include food and beverages, pharmaceuticals, and the automotive industry.

Key factors to look out for in washdown applications:

- Hygienic design: these bar lights must withstand harsh conditions, including chemical washdown and high pressures,

- Durability: good material choice and reliability under such operating conditions,

- Contrast: high brightness and high quality illumination to enhance image processing.

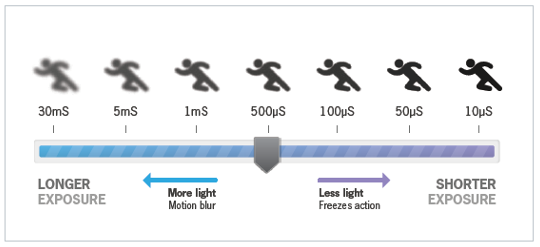

High-Speed Inspection Applications

The critical element for your system when you are dealing with a high-speed application is the camera’s exposure time. To ensure no motion blur, you need to ensure that no feature of the part you are inspecting moves more than a single pixel of the camera’s field of view.

The shorter the exposure time, the less light is reaching the camera’s sensor. To be able to freeze motion and enable a very low exposure time, you will need a very bright bar light. Consider using a bar light with integrated OverDrive function, such as our Modular M-EBAR, which is 2.4 times more intense in strobe mode for the first 30ms of the trigger signal.

For a real-life application example, read our case study from XXXXX. They inspected x and achieved x with y product.

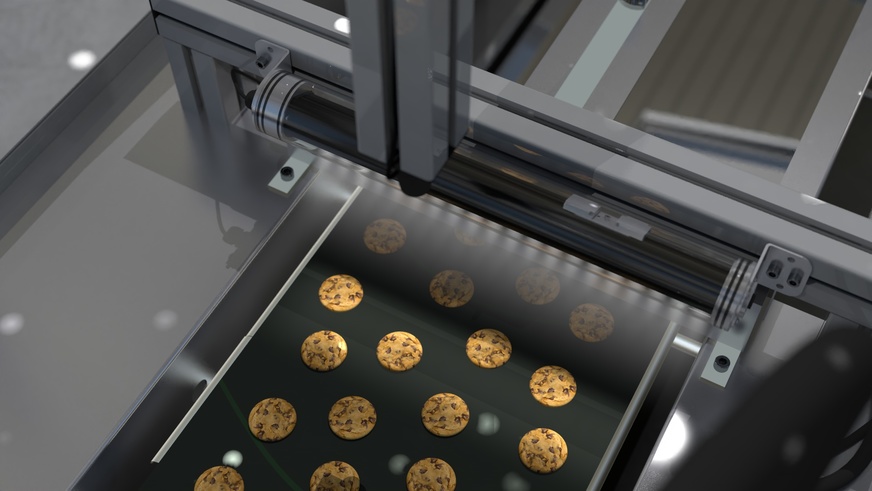

Line Scan Applications

In line scan applications, consistent illumination is crucial as the camera captures a continuous line of objects or surfaces. Bar lights must provide uniform and continuous lighting to ensure even exposure across the entire scan area. Bar lights should complement the high-speed operation of line scan cameras by delivering the required illumination without introducing motion blur.

Modular Bar Lights & Maximum Flexibility

Our modular bar lights are perfect for providing high quality illumination for a range of working distances and fields of view, allowing you to easily create different lighting techniques with just a few part numbers.

How is this achieved?

Our patented Angle Changers (ACs) use micro-optic films that shape the light output, providing 4 output angles: Narrow, Medium, Wide and Line light. You can easily attach them to our M-EBAR, EBAR+ and M-TBAR products to change the beam angle.

Fun fact: the EBAR+ Angle Changers can withstand the strength of a 100G acceleration, and a pulling test of 100 times the weight of itself.

How do you benefit from flexibility?

Using modular lighting allows for an easier testing process that requires less resources and downtime spent on configuring the lighting setup. Taking the guesswork out of the product selection process, the performance and flexibility of our Modular Range allow these products to cover many applications and make it easy to do adjustments at any stage of the project.

You also don’t need to worry about having to open up your product and compromise your IP rating! This way, your light is not exposed to dust or other contaminants (such as fingerprints), which can affect the repeatability of the imaging results.

The Curve Effect

Struggling with hot spots?

Changing the illumination output angle along the length of a single Modular Bar using Angle Changers allows you to tailor the homogeneity perceived by the camera. Optimising the perceived homogeneity on large FoV can also be achieved by using various Angle Changers on a cluster of Modular M-EBARs. This means you can eliminate hotspots anywhere in the FoV, giving increased read rates, and reduced costs of rework.

Bar Lights Product Comparison

PRODUCT

DIMENSIONS

COLOUR

AVAILABLE VERSIONS

IP PROTECTION

AC COMPATIBLE?

64 mm

White, Blue, Green, Red, IR

Standard

IP67

✓

125-500 mm

White, Blue, Green, Red, IR

Standard

IP65

✓

125-2500 mm

White, Blue, Green, Red, IR

Standard, Link, OverDrive

IP65

✓

125-1250 mm

UV 405

Standard, Link

IP65

✗

125-1250 mm

White, Blue, Green, Red, IR, UV405

Standard

IP69K

✗

125-2500 mm

White, Blue, Green, Red, IR

Standard, Link, OverDrive

IP65

✗

125-1250 mm

White, Blue, Green, Red, IR

Standard

IP69K

✗