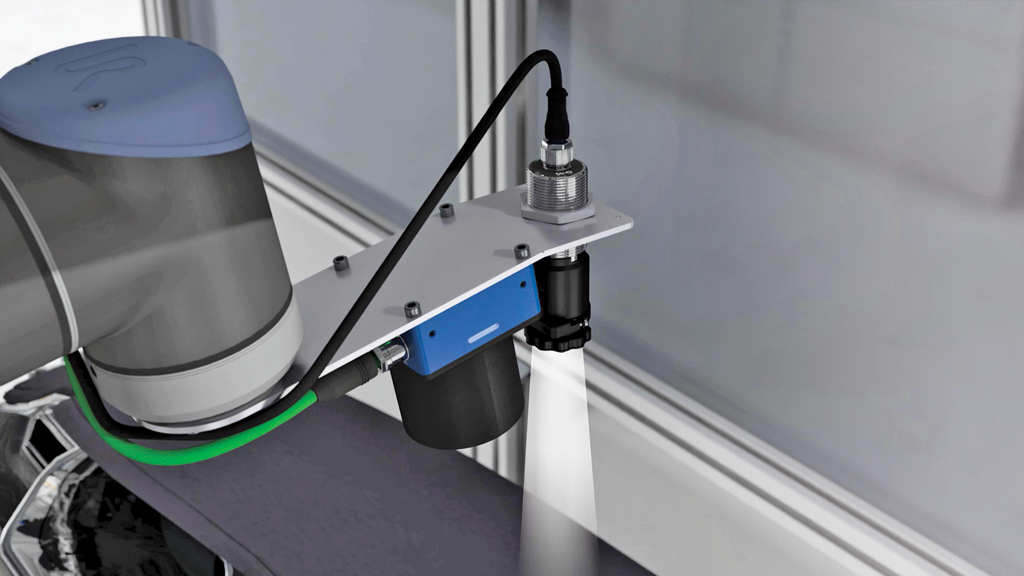

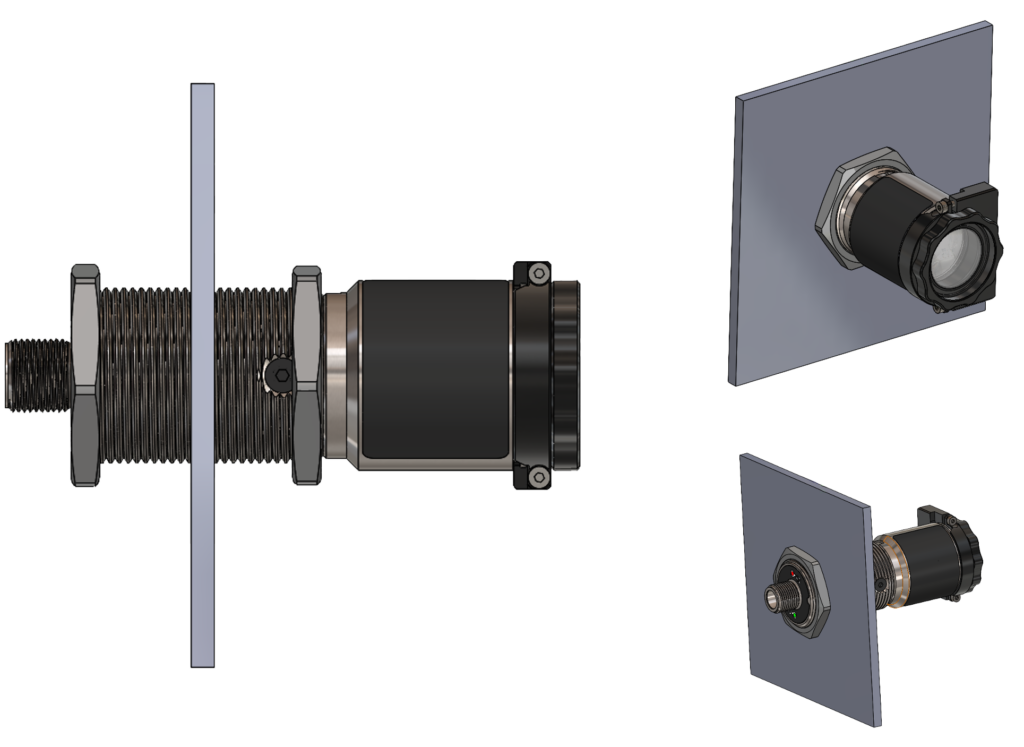

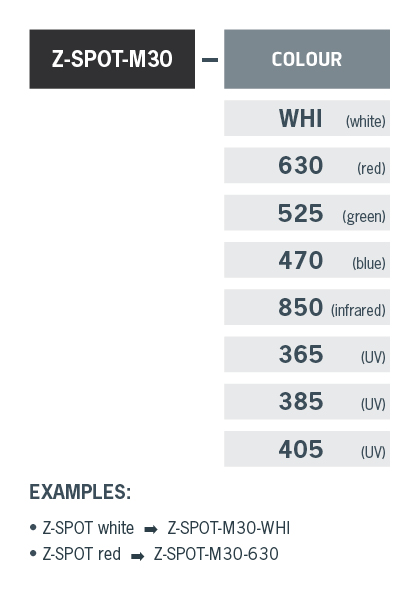

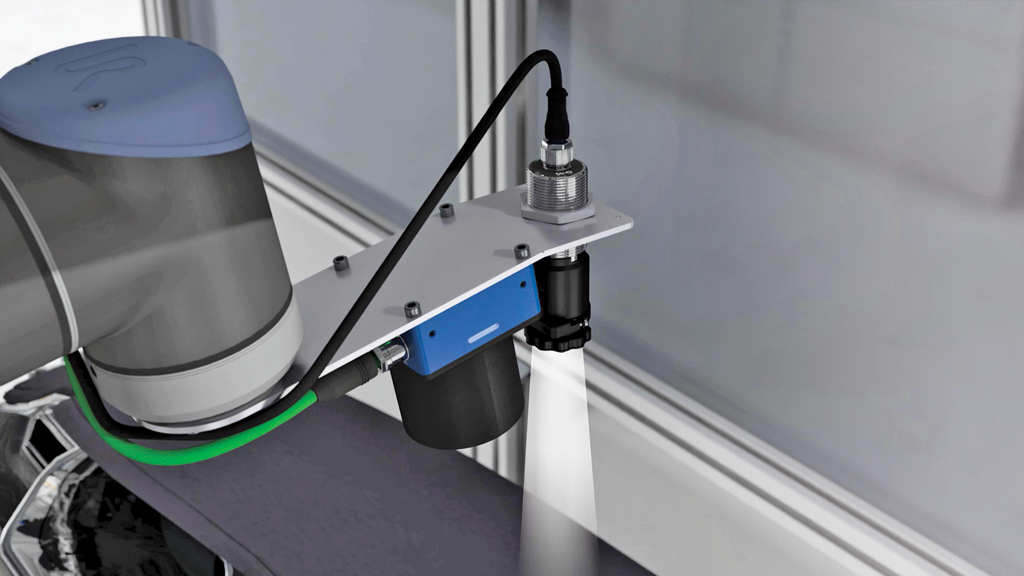

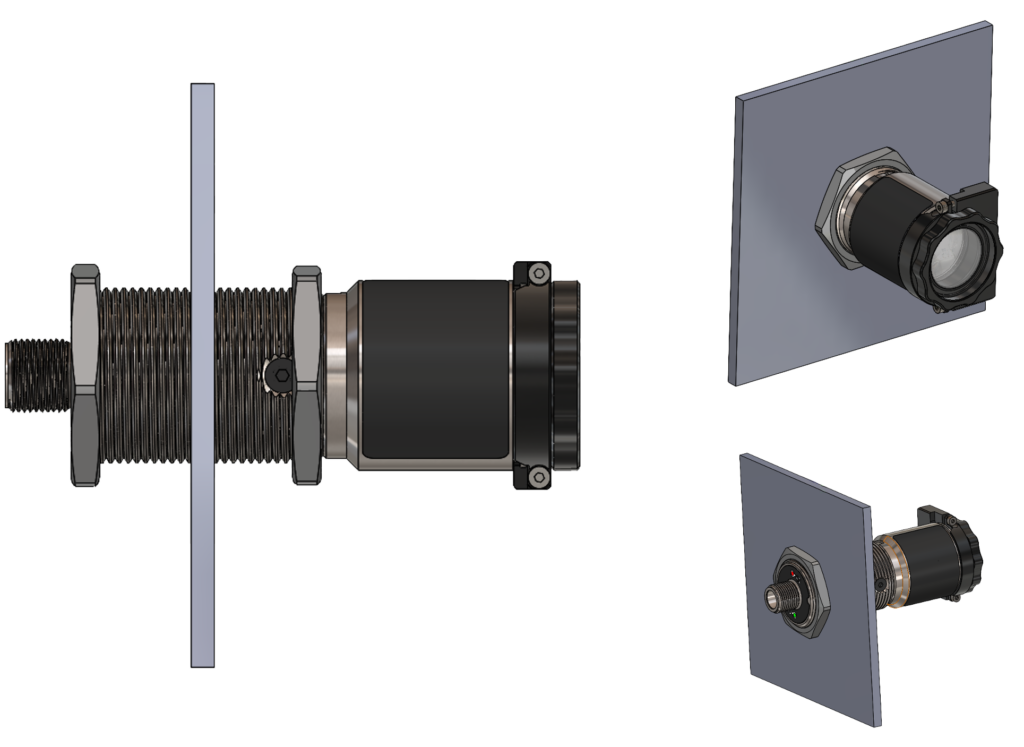

Homogeneous high-power machine vision spot light featuring a built-in lockable zoom lens with position repeatability. Enclosed in a durable IP67 aluminium housing, the Z-SPOT features flexible M30 mounting, M12 5-pin connector, integrated current control and a powerful Auto-Strobe OverDrive mode.

Spot lights are commonly used in automation applications where intense illumination is required in limited spaces. They provide targeted and focused lighting for projects inspecting specific details or features including robotics and pick-and-place, defect detection/quality control, component assembly inspection and more.

Spot lights are designed to emit a focused and directional beam of light to improve contrast and help the vision system capture more accurate images. The ability to control the direction and focus of the light is crucial, as it helps to reduce reflections and glare, improving the overall image quality.

Another key feature of machine vision spot lights is controllable intensity, which means they can be adapted to different materials and ambient lighting conditions. In strobe mode, the intensity of the light during the brief burst is crucial for capturing sharp images with a small aperture on the camera – for example, to inspect moving products on a conveyor belt without motion blur, the OverDrive strobe can be utilised.

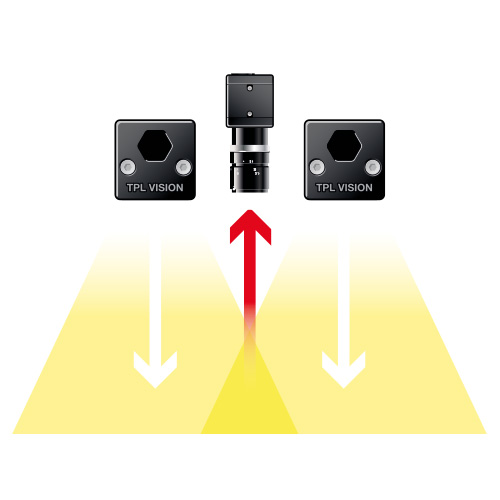

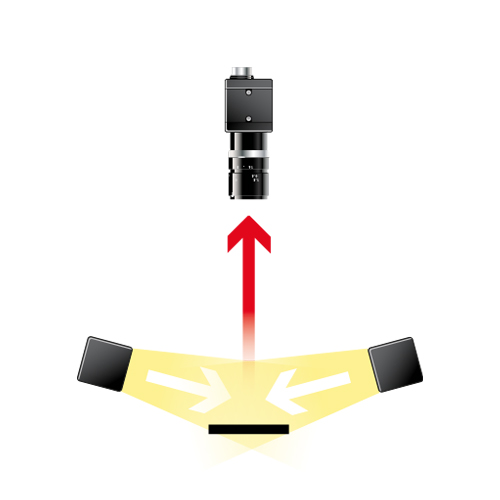

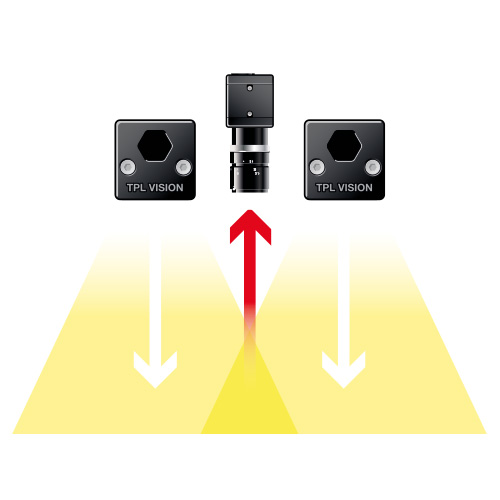

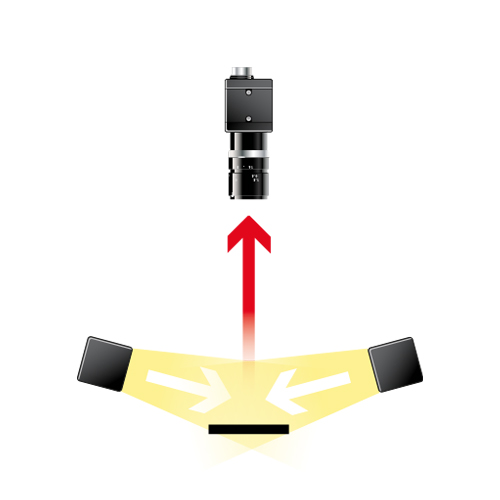

The angle at which the light is directed onto the object can also influence the perceived brightness. In bright field applications, spot lights are positioned at a high angle relative to the object, creating an even illumination. This type of illumination is often used in quality control applications, where a comprehensive inspection of the object’s surface is required. It ensures that defects, contaminants, or variations in colour are easily detectable.

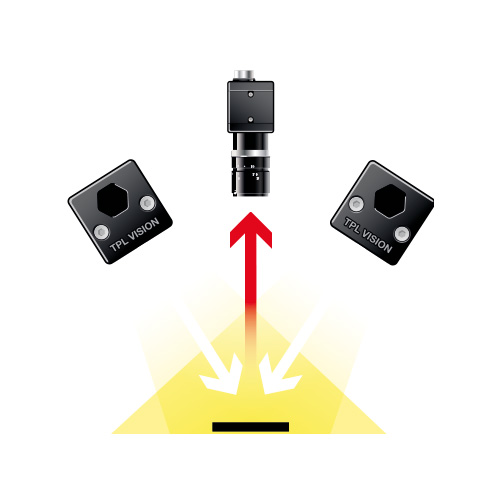

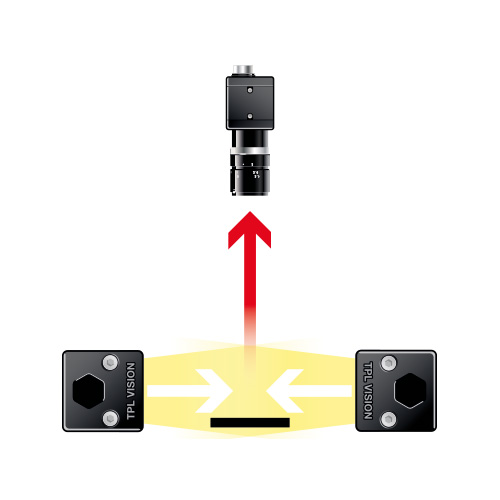

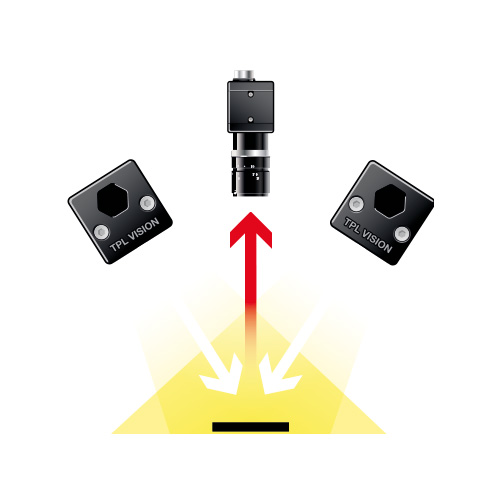

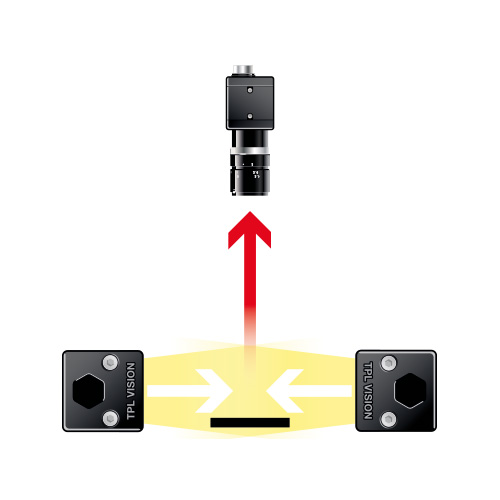

Spot lights are easily adapted to specific inspection tasks, allowing them to be used for low angle and dark field lighting techniques. In these applications, the lights are positioned at a low angle relative to the object being inspected, causing the incident light to be reflected away from the camera. This is useful for highlighting surface irregularities, such as scratches, dents, or texture variations.

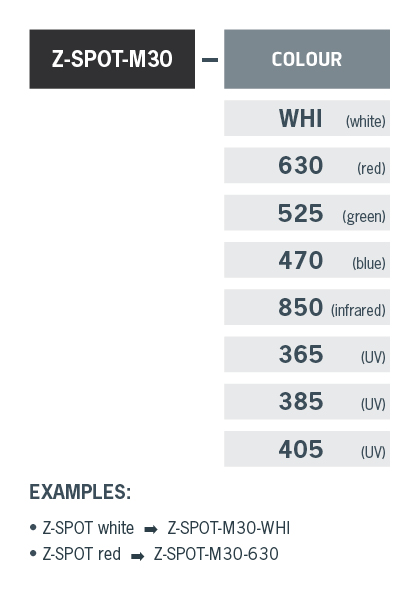

Available in three UV wavelengths (UV365, UV385, UV405), the Z-SPOT offers a comprehensive solution for UV inspection across a spectrum of applications. From UV seal inspection, glue inspection, and code reading, the Z-SPOT can aid with the detection of fluorescent materials in continuous or strobe modes. Its small footprint ensures seamless integration into tight workspaces.

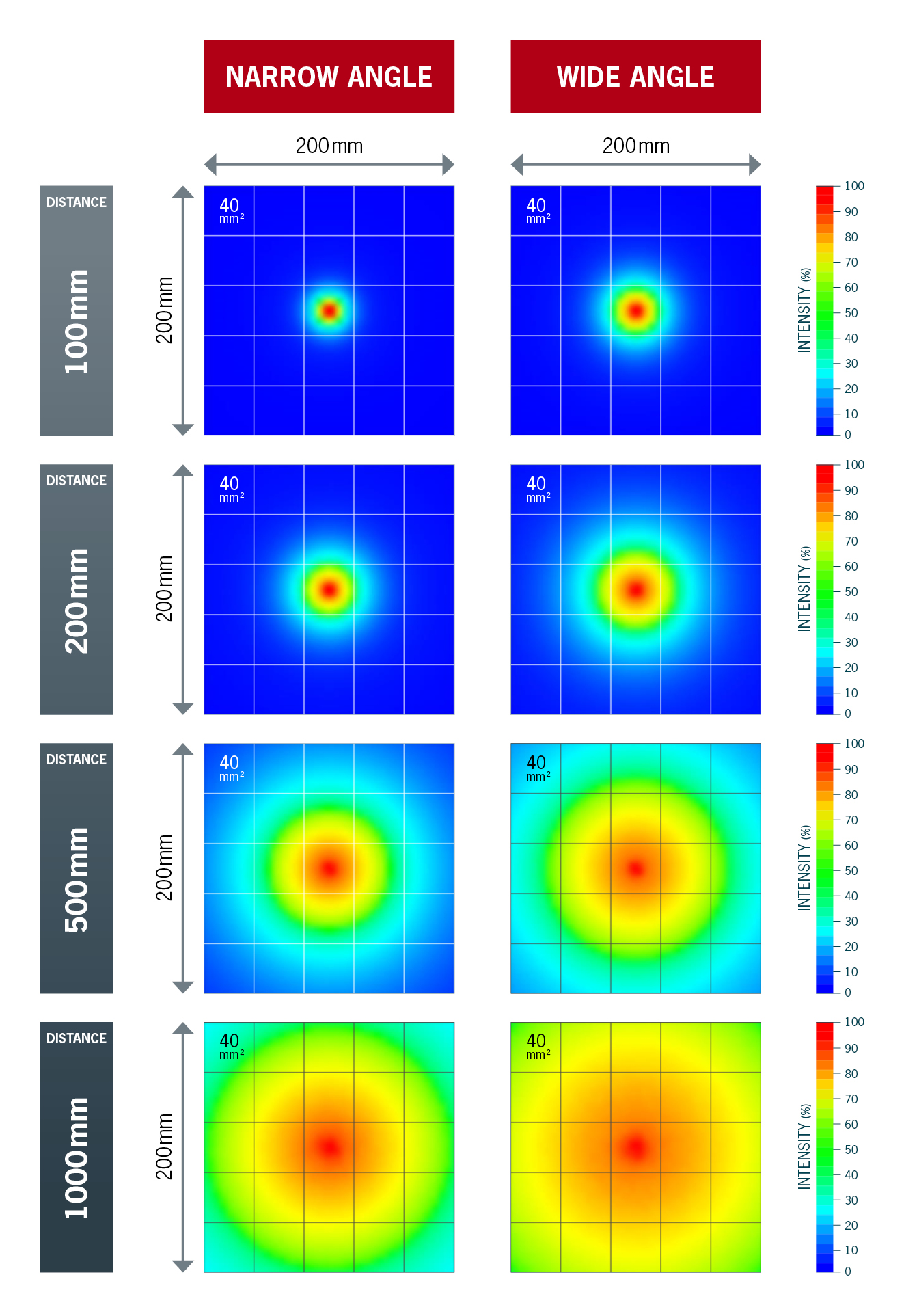

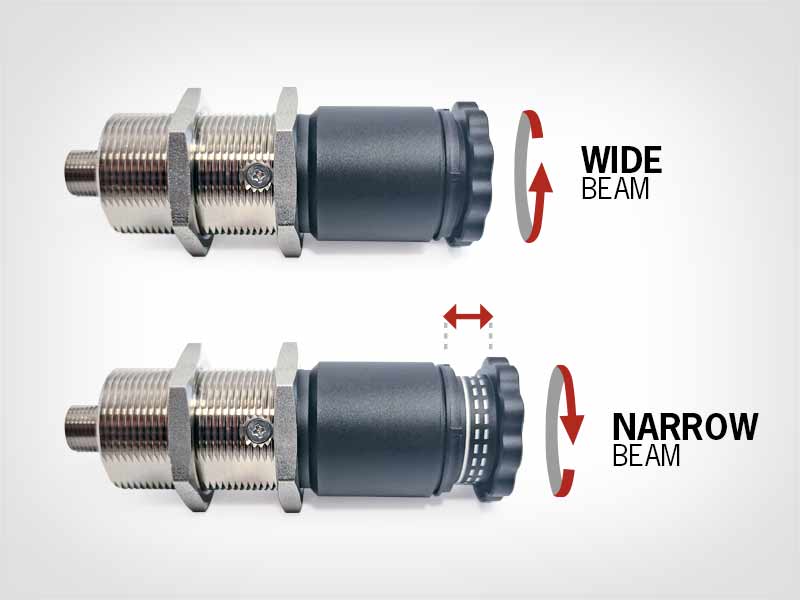

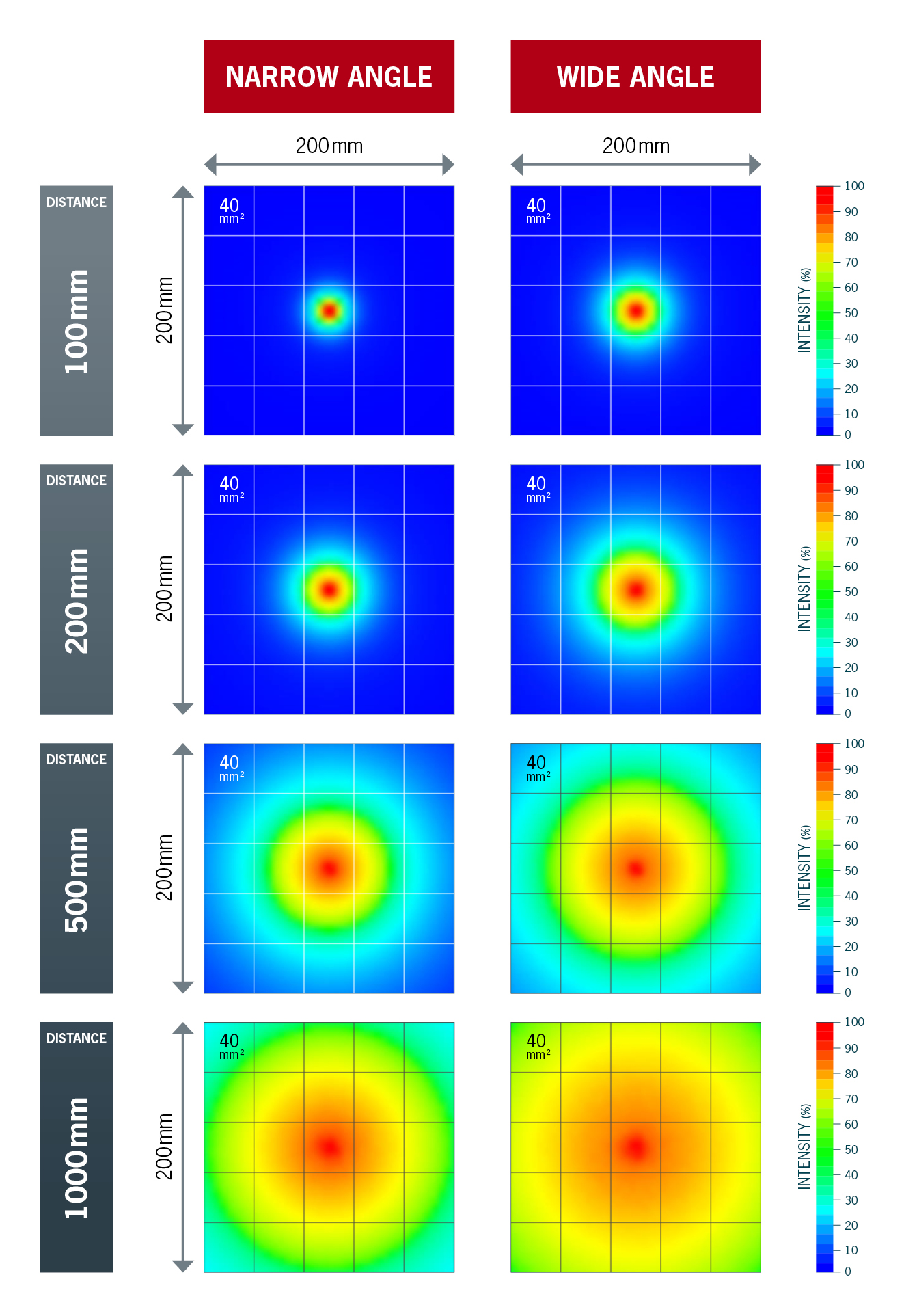

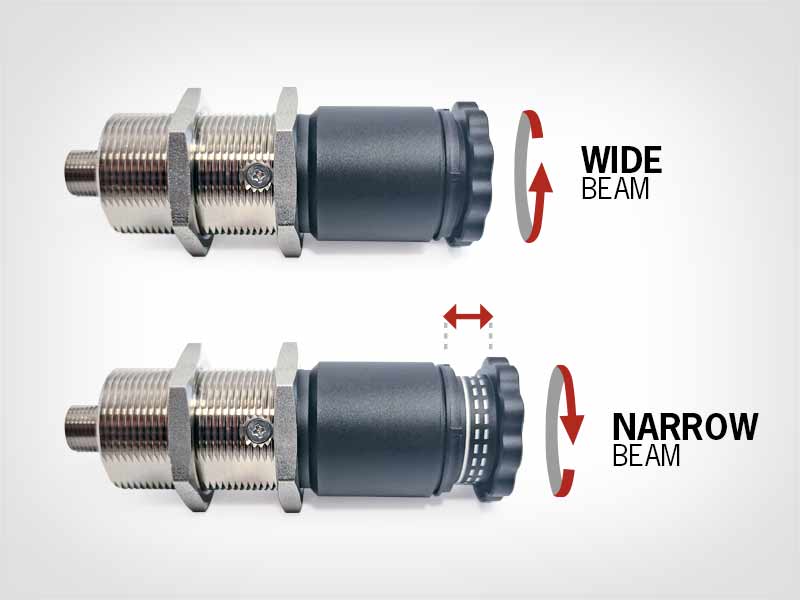

The Z-SPOT features a built-in lockable zoom lens with position repeatability, providing an exceptional range of field of view, working distance and brightness variability.

Bitte klicken Sie auf die nachfolgenden Tabs.

Spot lights are commonly used in automation applications where intense illumination is required in limited spaces. They provide targeted and focused lighting for projects inspecting specific details or features including robotics and pick-and-place, defect detection/quality control, component assembly inspection and more.

Spot lights are designed to emit a focused and directional beam of light to improve contrast and help the vision system capture more accurate images. The ability to control the direction and focus of the light is crucial, as it helps to reduce reflections and glare, improving the overall image quality.

Another key feature of machine vision spot lights is controllable intensity, which means they can be adapted to different materials and ambient lighting conditions. In strobe mode, the intensity of the light during the brief burst is crucial for capturing sharp images with a small aperture on the camera – for example, to inspect moving products on a conveyor belt without motion blur, the OverDrive strobe can be utilised.

The angle at which the light is directed onto the object can also influence the perceived brightness. In bright field applications, spot lights are positioned at a high angle relative to the object, creating an even illumination. This type of illumination is often used in quality control applications, where a comprehensive inspection of the object’s surface is required. It ensures that defects, contaminants, or variations in colour are easily detectable.

Spot lights are easily adapted to specific inspection tasks, allowing them to be used for low angle and dark field lighting techniques. In these applications, the lights are positioned at a low angle relative to the object being inspected, causing the incident light to be reflected away from the camera. This is useful for highlighting surface irregularities, such as scratches, dents, or texture variations.

Available in three UV wavelengths (UV365, UV385, UV405), the Z-SPOT offers a comprehensive solution for UV inspection across a spectrum of applications. From UV seal inspection, glue inspection, and code reading, the Z-SPOT can aid with the detection of fluorescent materials in continuous or strobe modes. Its small footprint ensures seamless integration into tight workspaces.

The Z-SPOT features a built-in lockable zoom lens with position repeatability, providing an exceptional range of field of view, working distance and brightness variability.

Bitte klicken Sie auf die nachfolgenden Tabs.