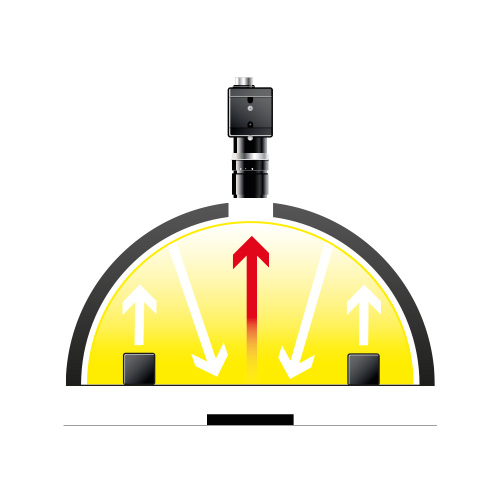

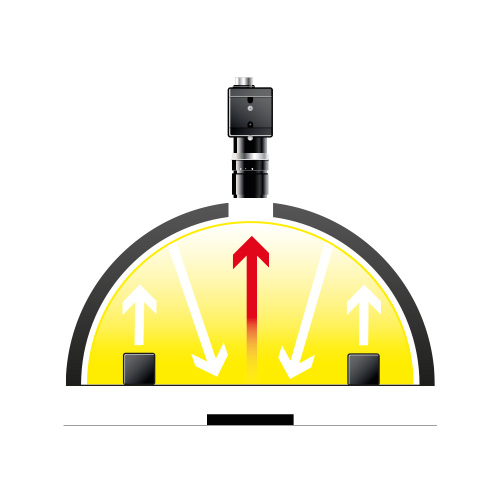

TPL Vision’s Fluorescence Imaging Solution* (FIS) ist eine flexible Mehrwellenlängen-UV-Domleuchte, die für Anwendungen in der Authentifizierung, Rückverfolgbarkeit und Fluoreszenzinspektion geeignet ist. . Aufgrund ihres einzigartigen Designs, das Benutzern ermöglicht, mehrere UV-Wellenlängen (UV365, UV395 und UV405) zu testen und auszuwählen, eignet sich das FIS für die Inspektion von Banknoten und Steuerzeichen sowie für die Prüfung verschiedener UV-Sicherheits- und Markenschutzmerkmale, die bei pharmazeutischen Produkten, Elektronik und Luxusgütern wie Parfums und Aftershaves, Tabak- und Alkoholprodukten sowie Designermarken verwendet werden.

Das FIS ist mit jeder Kamera im sichtbaren Spektrum kompatibel und bietet eine Komplettlösung für UV-Anwendungen, die zudem die Sicherheit der Bediener maximiert, indem direkte UV-Strahlung durch die Kuppel und den integrierten Filter blockiert wird.

*Patent angemeldet

Das Vision Systems Design Innovators Awards-Programm würdigt die innovativsten Produkte und Dienstleistungen in der Vision- und Bildverarbeitungsbranche. Die Fluorescence Imaging Solution hat im Jahr 2023 eine Bronzemedaille gewonnen.

Bitte klicken Sie auf die nachfolgenden Tabs.

UV (ultraviolet) rays are electromagnetic radiations situated between 280 and 400 nm. Although invisible for the human eye, these can be observed by fluorescence imaging. When submitted to UV wavelengths, fluorescent substances absorb and re-emit UV light as visible, longer wavelength radiation, typically blue (470 nm) or green (525nm). This can be inspected by a camera through the use of filters to block out any unwanted UV wavelengths.

Common ultraviolet light uses include medical and industrial processes used for disinfection and hygiene control, as well as commercial applications detecting security inks and fluorescent anti-counterfeiting packaging features. UV-fluorescent security markings are used to fight counterfeiting in the form of 2D codes, barcodes, alpha numeric codes, images and graphics, safeguarding brand authenticity and supporting supply chain tracking. Depending on the type of ink used, these features can become fluorescent at a wide range of UV wavelengths, but more specialised types of inks will only react to a narrow band of wavelengths. Traceability logos and codes come with the ability of embedding various types of information (batch numbers, inspection results, etc.) without affecting the design of the product packaging.

UV inks are often used as enhanced security features for identity documents such as cards and passports, as well as for excise stamps. These usually combine overt (visible to the naked eye) and covert (only visible using a tool) features. Covert features such as UV-fluorescent text or symbols make it harder to create counterfeits but are still easily detectable for verification purposes.

Das Vision Systems Design Innovators Awards-Programm würdigt die innovativsten Produkte und Dienstleistungen in der Vision- und Bildverarbeitungsbranche. Die Fluorescence Imaging Solution hat im Jahr 2023 eine Bronzemedaille gewonnen.

Bitte klicken Sie auf die nachfolgenden Tabs.

UV (ultraviolet) rays are electromagnetic radiations situated between 280 and 400 nm. Although invisible for the human eye, these can be observed by fluorescence imaging. When submitted to UV wavelengths, fluorescent substances absorb and re-emit UV light as visible, longer wavelength radiation, typically blue (470 nm) or green (525nm). This can be inspected by a camera through the use of filters to block out any unwanted UV wavelengths.

Common ultraviolet light uses include medical and industrial processes used for disinfection and hygiene control, as well as commercial applications detecting security inks and fluorescent anti-counterfeiting packaging features. UV-fluorescent security markings are used to fight counterfeiting in the form of 2D codes, barcodes, alpha numeric codes, images and graphics, safeguarding brand authenticity and supporting supply chain tracking. Depending on the type of ink used, these features can become fluorescent at a wide range of UV wavelengths, but more specialised types of inks will only react to a narrow band of wavelengths. Traceability logos and codes come with the ability of embedding various types of information (batch numbers, inspection results, etc.) without affecting the design of the product packaging.

UV inks are often used as enhanced security features for identity documents such as cards and passports, as well as for excise stamps. These usually combine overt (visible to the naked eye) and covert (only visible using a tool) features. Covert features such as UV-fluorescent text or symbols make it harder to create counterfeits but are still easily detectable for verification purposes.