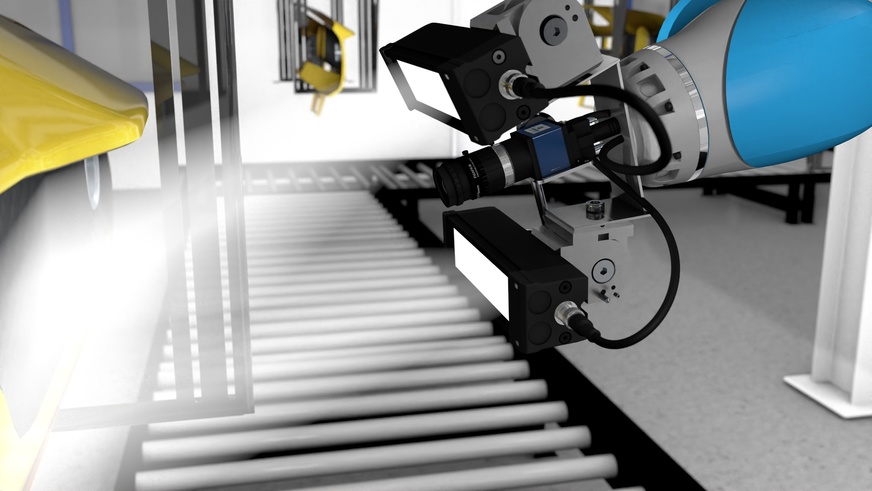

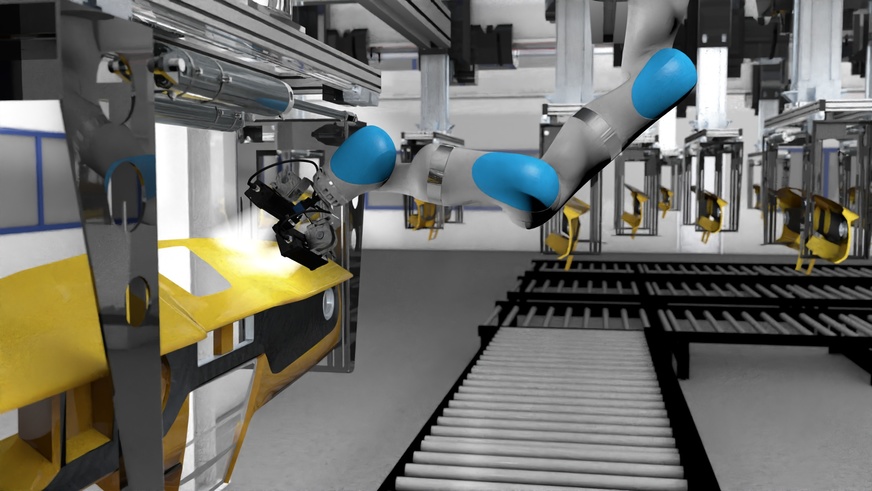

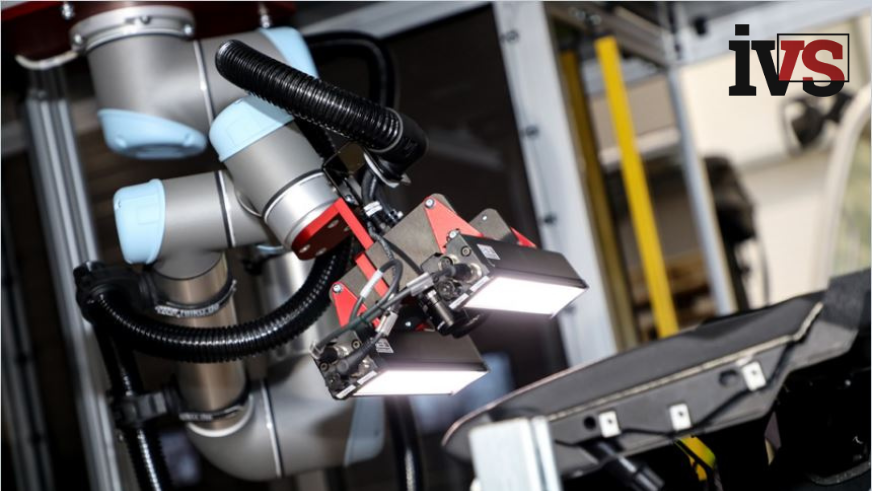

A key stage of the car assembly process, the verification of component presence/positioning and quality control is carried out using a camera-based vision system. The addition of powerful diffuse bar lights onto a collaborative robot (cobot) enhances the camera’s ability to consistently monitor curved surfaces and diverse materials (such as metallic and black surfaces) within a single operational cycle.

The implementation of diffuse white light on both sides of the camera plays a pivotal role in creating uniform illumination that’s suited to varied working distances. This illumination arrangement ensures consistent lighting conditions, thereby facilitating effective quality control of the parts.

Zurück

Weiter

Herausforderungen

- Variation in surface properties: The verification process involves inspecting curved surfaces and diverse materials, which can lead to challenges in achieving consistent and accurate image capture due to varying levels of reflectance and changes in surface geometry.

- Process reliability: Inconsistent lighting can lead to false defects. For instance, a shadow might be mistaken for a physical feature, causing the system to signal the presence of a component that isn’t actually there (false positive). Likewise, if critical features are not properly illuminated and captured by the camera, it can lead to the component being falsely marked as missing or misaligned, resulting in a false negative.

- Variety of working distances: the working distance between the camera and the inspected parts might vary. This could lead to variations in lighting conditions and image quality, affecting the reliability of the process.

Lösung

- To prevent false defects or incorrect component assessments, consistent lighting conditions are crucial.The chosen bar lights are able to provide robust illumination for all kinds of materials, including highly reflective and metallic parts.

- By scattering light evenly across surfaces, the diffuse BLBAR+ minimises shadows and highlights, reducing the chances of false positives and negatives occurring during the verification process.

- The unique positioning of the two bar lights ensures components are uniformly lit even at variable working distances.

Video - Robot Inspection Cell with Automated Guided Vehicle

Play Video about screenshot 2023 08 16 at 11.18.31