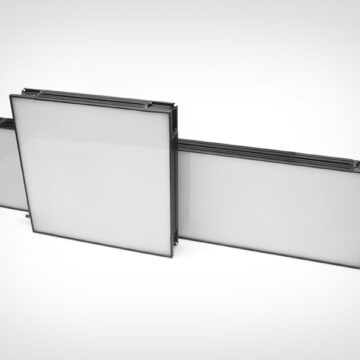

Backlights offer high homogeneity surface illumination for silhouette inspection and other machine vision applications, such as liquid fill level and presence/absence. TPL Vision’s backlights are designed to create the best contrast for image processing in strobe or continuous modes. They come with narrow framing and high homogeneity, enabling them to tackle even the most challenging machine vision projects. Illuminate any surface from small 50×50 mm areas to large fields of view, confined spaces to very large surface areas.

Showing all 7 results

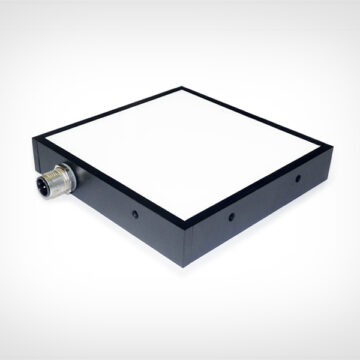

The HPBACK is a high-power backlight solution for Machine Vision applications.

This product is the next evolution of TPL Vision’s high running MBACK+ Standard product, carrying significant product enhancements.

Including: brightness level up to 45 kLux*, new connector making it easier and more cost effective to integrate, improved rising and falling times of 15μs and 10μs respectively and custom sizes available in 1cm steps (from 200 x 200mm up to 500 x 500mm or 1000 x 200mm).

The robust Aluminium casing of the product can be manufactured to sizes from 200 x 200mm up to 900 x 900mm or 1900 x 400mm. This range topping backlight solution is perfect for high speed backlighting applications that require intense luminous flux. Available in Red, White and Infrared, all with extremely high brightness and surface homogeneity of up to 85%. This is the solution for all backlighting applications and quality control tasks, such as: presence/absence, analysing edge defects, liquid fill level measurement and silhouetting.

(* in continuous working, measured at the surface with the WHITE LED version of the product).

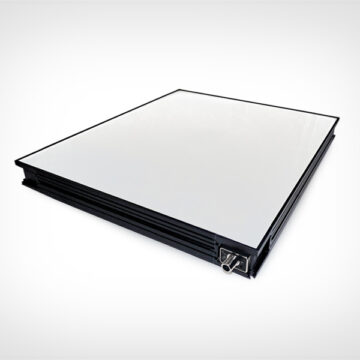

The connector can be placed on any side of the MBACK+, which can then be set up on any kind of conveyor belts. At the basis of the connector, 2 LED indicators show if the product is powered and if the strobe mode is on. The MBACK+ is perfectly adapted to quality control tasks, such as: presence/absence, edge defects, material lack. It can also be used as a direct diffuse lighting solution, to inspect shiny workpieces.

The semi-collimated CMBACK+ is a powerful and very diffuse backlight, dedicated to many machine vision applications. With high powerful LED and specific lenses, it creates a very intense illumination, that helps cameras to clearly see workpieces shapes.

Thanks to its thin borders, the new SMALL SBACK II is a backlight both powerful and homogeneous, that perfectly fits confined spaces. Settled under the objects to be controlled, the SMALL SBACK II highlights the global shape of the objects (shadow puppet effect), which enables the verification of possible outline defects and material lacks.

TPL Vision’s semi-collimated backlight, the CSBACK is the perfect illumination choice for the inspection or measurement of clear plastics and rounded parts. Collimated light by definition has parallel light rays, and therefore spreads minimally as it propagates, helping to create high-contrast images needed for precise edge detection and defect analysis.

Key application areas include the inspection of objects with rounded edges and clear parts, which may be challenging to inspect with traditional backlights due to the lack of contrast. A collimated light allows users to eliminate this effect by providing a narrower illumination angle that stops the light from wrapping around rounded parts. This also means that images of clear parts no longer appear “washed out”. The edges are more clearly defined, and details are seen with improved contrast, leading to high-quality images and increased accuracy.

Many machine vision systems use multiple light sources. LED panels equipped with white diffusers can interfere with the camera and reduce the efficiency of other illumination sources by scattering light in unintended directions, creating unwanted reflections, and diminishing contrast, which can compromise the quality of the inspection.

The Black & Light (Bn’L) by TPL Vision offers an innovative solution compatible with most vision applications. When the light is on, it works as a traditional homogeneous backlight, highlighting the shape of objects and creating a uniform silhouette. When it’s off, it becomes a matte black background. This is extremely useful when other illuminations are used, as the black background absorbs scattered light and ensures that panels equipped with white diffusers do not interfere with how light is perceived by the camera.

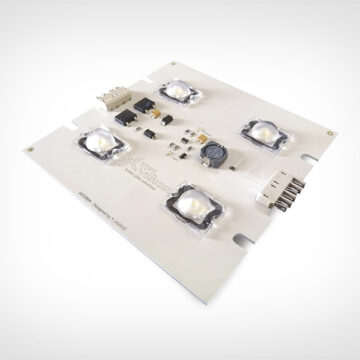

Equipped with 4 high powerful LEDs, the LED BRICK modules by TPL Vision can be easily interconnected. You just have to plug few modules of LED BRICK all together to get very large lighting areas, easily upgradable according to the vision application’s features. If you just add an opaque diffuser on the top of the configuration, you get a perfectly homogeneous backlight, very appreciated by machine vision specialists. The LED BRICK lighting solutions can rely on the LED advanced technology at very affordable prices.