In the automotive engine manufacturing sector, ensuring reliable quality control at the end of the production line is essential to prevent defective engines from being shipped.

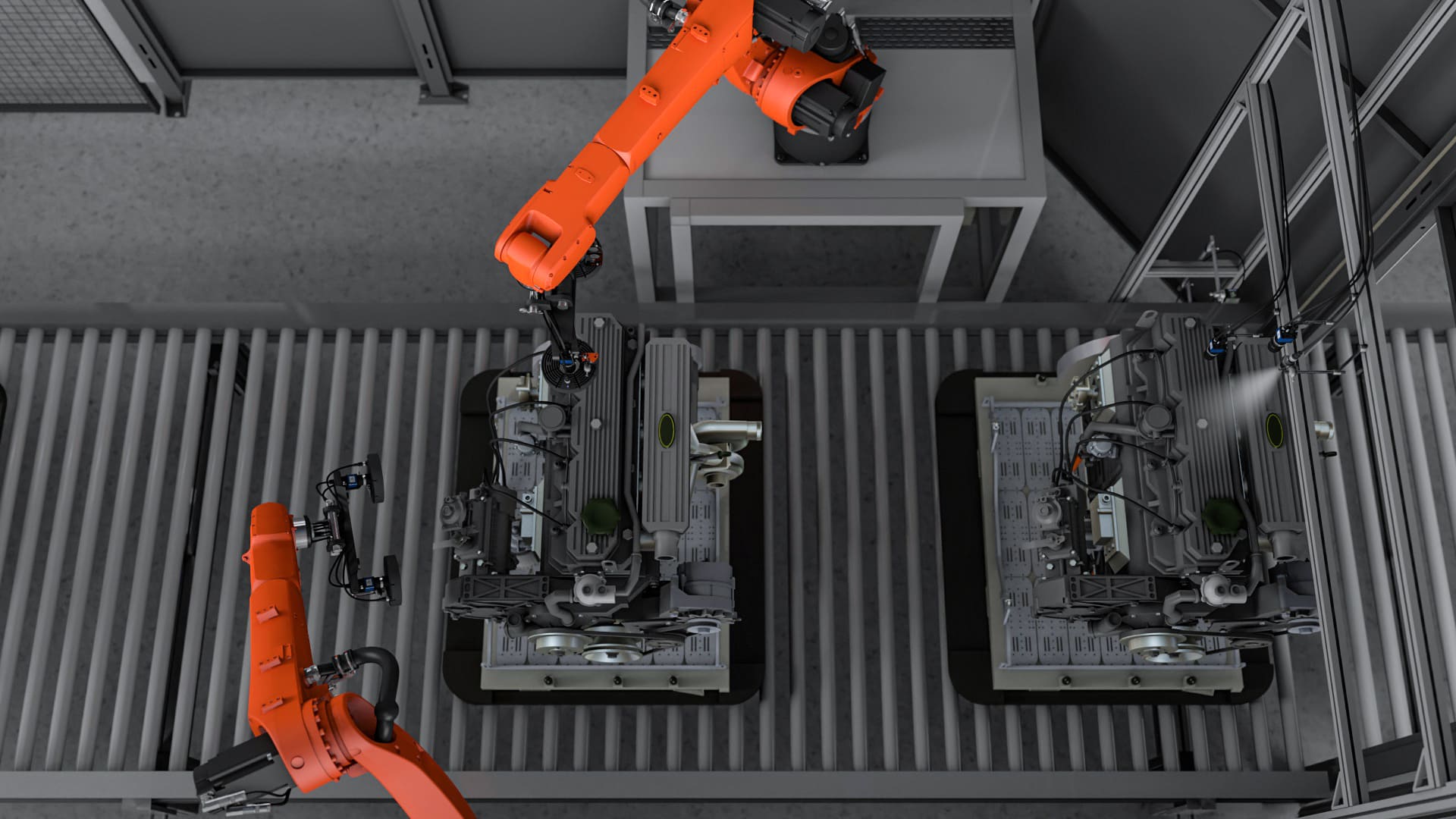

To achieve this, a fully automated visual inspection system is deployed at the end of each production line. This system consists of multiple cameras, lenses, and lighting mounted on robotic arms, meticulously inspecting the engine block to verify that all components and attachments are correctly installed.

Our M-TRING was used in this application to provide uniform illumination at various working distances without shadows or reflections. The solution was seamlessly integrated with the cameras, which were mounted on multiple robotic arms.

Challenges

- Inconsistent Lighting – Engine blocks come in various designs, shapes, and sizes with complex and often reflective surfaces. If the lighting in the machine vision system is not precise, shadows or reflections can interfere with capturing high-quality images.

- Integration with System Components – The vision system consists of multiple parts, including several cameras, lenses, and lighting, all mounted on robotic arms. The lighting solution needed to be compact and easy to install without interfering with the other system components.

- Inspection Accuracy and Efficiency – Operating at the end of a fast-paced production line, the system had to deliver precise and reliable inspection results without delays or disruptions. The lighting had to be highly consistent and synchronized with the image capture process to maintain accuracy.

Solution

- Uniform and Controlled Illumination – Integrating the opaque version of the M-TRING ensured consistent lighting across the entire engine block. This solution minimized harsh shadows and reflections on shiny surfaces, enhancing image quality.

- Lightweight and Robust Design – With its compact and durable construction, the M-TRING seamlessly integrated into the machine vision system. Its small modular form factor allowed easy installation and optimal positioning among the system’s components.

- Precision-Optimized LEDs – Bright, uniform illumination enabled the vision system to operate with maximum accuracy. In OverDrive mode, the M-TRING’s 12 powerful LEDs delivered intense lighting, perfectly synchronized with the camera system to match the image capture cycle.

Related products

The implementation of the M-TRING within the automated visual inspection system has significantly improved quality control at the end of the production line. By addressing challenges such as inconsistent lighting, complex integration, and the need for precise inspection, the M-TRING’s uniform and controlled lighting, lightweight design, and high-performance LEDs have enhanced system efficiency. This has enabled accurate, high-quality image capture while keeping pace with the production line’s demanding requirements.