The Essential ELINE is a line scan light for machine vision applications, ideal for long working distance applications of fabric- and web inspection, geometric measurement, quality control applications. Available in a variety of sizes up to 2.5m to cover a range of line scan applications. The collimated light variation is the most adaptable version and can work at long working distances, from 25mm up to 1000mm, and generates a beam width of around 2cm. Diffuser attachments can be added for various lighting effects, making it perfect for machine vision applications such as surface inspection lighting or edge detection.

Line scan technology is a machine vision method that captures high-resolution images of objects as they move through a single line of pixels, rather than capturing an entire area at once. This method is particularly useful for inspecting continuous surfaces or objects that are in continuous motion, such as textiles, paper, metal, plastic films, rubber or composites. By scanning one line at a time, line scan technology ensures detailed inspection with consistent image quality across the entire object.

Area scan and line scan are two approaches to image acquisition using different methods.

Area scan cameras capture the image of an object using a 2D matrix of pixels. Within a line scan camera, pixels are aligned in a single row along the width of the field of view. The camera captures images continuously, building up a two-dimensional image as the object being inspected is moved perpendicularly past the line of pixels.

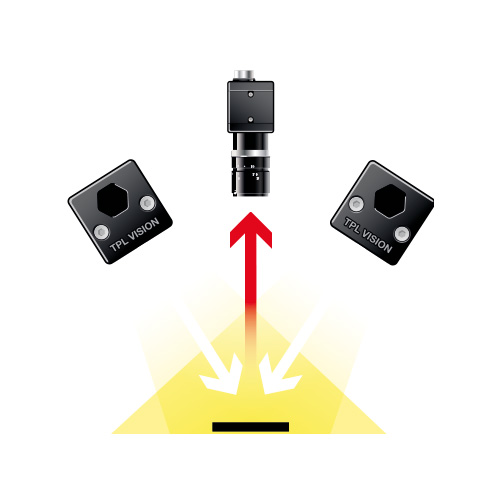

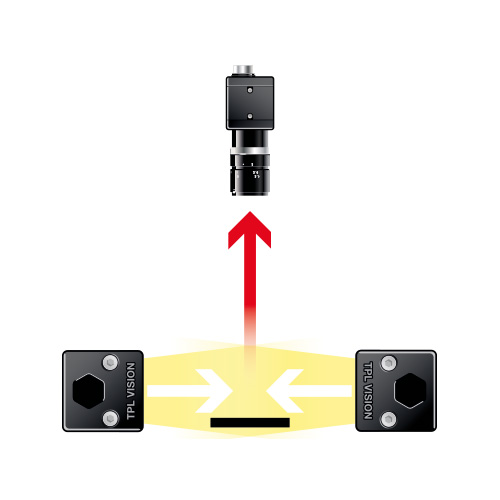

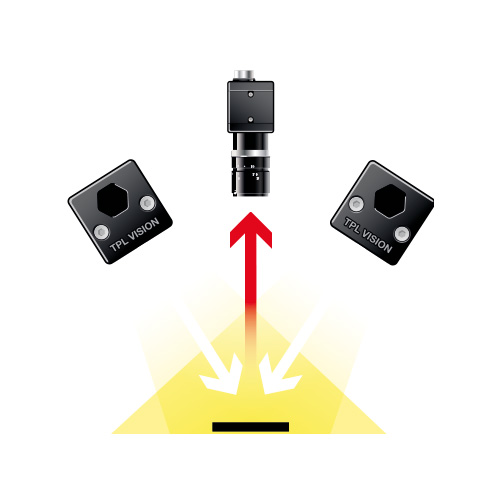

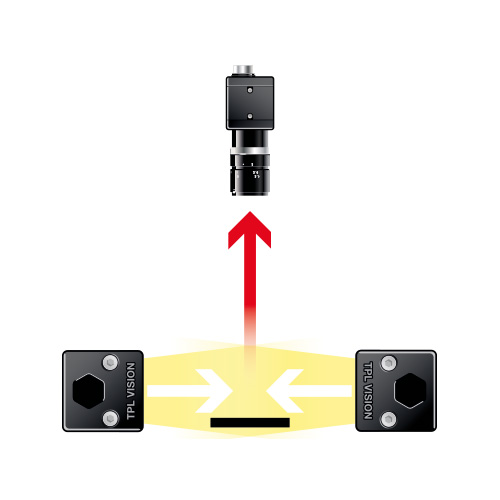

A line scan light, or line lighting, is an illumination system specifically designed for use with line scan cameras in machine vision applications. It provides uniform, high brightness lighting across the entire line being scanned, ensuring consistent and clear image capture. High power lighting is critical for achieving the uniformity needed in line scan technology.

Bitte klicken Sie auf die nachfolgenden Tabs.

Line scan technology is a machine vision method that captures high-resolution images of objects as they move through a single line of pixels, rather than capturing an entire area at once. This method is particularly useful for inspecting continuous surfaces or objects that are in continuous motion, such as textiles, paper, metal, plastic films, rubber or composites. By scanning one line at a time, line scan technology ensures detailed inspection with consistent image quality across the entire object.

Area scan and line scan are two approaches to image acquisition using different methods.

Area scan cameras capture the image of an object using a 2D matrix of pixels. Within a line scan camera, pixels are aligned in a single row along the width of the field of view. The camera captures images continuously, building up a two-dimensional image as the object being inspected is moved perpendicularly past the line of pixels.

A line scan light, or line lighting, is an illumination system specifically designed for use with line scan cameras in machine vision applications. It provides uniform, high brightness lighting across the entire line being scanned, ensuring consistent and clear image capture. High power lighting is critical for achieving the uniformity needed in line scan technology.

Bitte klicken Sie auf die nachfolgenden Tabs.