In the world of machine vision, industrial lighting plays a critical role in enhancing image quality for vision inspections, precision measurements, and automated object identification. Proper illumination ensures high brightness and homogeneity, making objects clearly visible and enabling the camera system to capture high-quality images with precision.

Two commonly used industrial lighting solutions in machine vision are line scan lighting and area scan lighting. Each method offers unique advantages depending on the application requirements. This article explores the key features of both lighting solutions and their respective benefits.

Line Scan Lighting

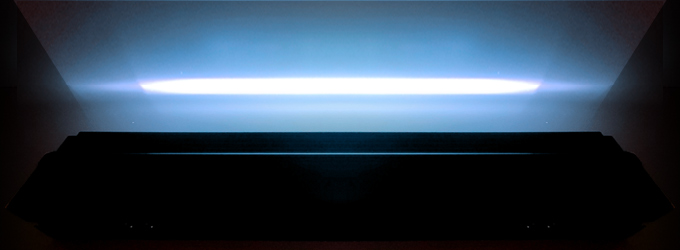

Line scan illumination is a popular technique in LED lighting for high-speed machine vision inspection applications, such as print inspection and web inspection. Working in tandem with a line scan camera, these lights generate an intense, narrow beam that illuminates a moving object line by line. This method is particularly beneficial for web inspection applications and industries dealing with continuous materials such as textiles, paper, metal, plastic films, rubber, and composites.

Line scan cameras capture images one line at a time, which are then stitched together to form a complete, high-resolution image. These solutions offer superior inspection speeds and lighting accuracy as the light can be mounted very close to the inspected line; meaning users can leverage higher intensity and homogeneity from the light source. Variants of line scan lighting include focused, collimated, backlight, and coaxial lights which are used for challenging applications, each designed for specific inspection needs.

Area Scan Lighting

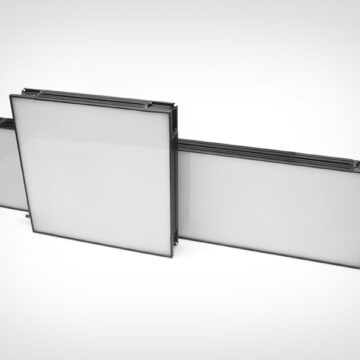

Area scan lighting is valuable for static inspections where objects stay within a controlled field of view (FoV). By capturing entire frames at once, area scan cameras are easier to install than line scan and can effectively detect multiple parts in a fixed FoV. They are perfect for defect inspection, presence absence, robotic guidance and quality control. Unlike line scan solutions, which always requires motion to work, area scan can be done with or without motion.

Area scan lighting is designed to provide uniform illumination across a target area. This is the same for line scan lighting, however, in addition area scan provides a new axis so that lighting is radial around the target to easily highlight additional edges and details. This ensures clear, high-quality image capture for industrial automation applications such as surface inspection, quality control, and automated measurement systems where objects remain static.

Precise and uniform lighting is essential in area scan applications to minimise shadows and reflections. Various types of area scan lights, including bar lights, diffused lights, ring lights, and flat light panels, are available to suit different inspection scenarios.

Key Differences Between Line Scan and Area Scan Lighting

- Speed and Motion Adaptability: Line scan lighting is optimised Line scan requires a precise set up where the light must be paired with an encoder to balance out fluctuations in conveyor speed. Whereas area scan can generate a sharp image as long as the exposure time is considerably lower than the required exposure to eliminate motion blur.

- Lighting Uniformity and Shadow Management: Line scan lighting, with its narrow illumination, can be more effective for highlighting surface defects and textures by controlling light angles more precisely. It is easier to ensure homogeneity and high brightness with line scan lighting since it is focused on a fixed line, users can mount the light very close to the surface which actually makes it easier to get consistency with the lighting over the line by line image. For area scan, customers must ensure that they understand how the light will be reflected on their target area and select a light that is larger than the inspected area to ensure uniform lighting.

- Field of View (FoV) and Resolution: Area scan lights operate at a fixed height, whereas line scan solutions have an option to select the height of the inspected image, meaning it offers a wider FoV. Line scan lighting also captures high-resolution images line by line, which can be advantageous for inspecting long or continuous objects without requiring an extremely high-resolution area scan camera.

- Cost Considerations: For a large FoV, line scan solutions can be more cost-effective as they require smaller sensors and optics compared to high-resolution area scan cameras, which may need extensive lighting setups. On the other hand, area scan is much easier to set up as it does not require an encoder.

- Application Suitability: Line scan lighting is ideal for industries like print inspection, web inspection, and textile manufacturing, where continuous material flows need inspection. Area scan lighting is preferred for defect detection, robotic guidance, and automated assembly verification where entire objects need to be analysed in one capture.

- Adaptability to Dynamic Imaging: While area scan lighting is commonly used for static inspections, it is also effective for dynamic imaging when synchronized with motion control systems. This makes it valuable in applications where objects are moving but need to be captured in discrete frames for analysis.

Choosing the Right Solution for Your Application

Cost Efficiency of Line Scan Lighting: In ideal lighting configurations for area scan, the light should be double the size of the inspected area. This means that for large fields of view that are over 1000mm, the light can be very expensive. Using line scan allows customers to use a smaller, less expensive light which can be focused on a smaller area (depending on the mechanical constraints of the application).

Selecting the appropriate lighting method depends on several factors, including object size, motion speed, and required resolution:

- For static inspections on conveyor belts or stationary objects, area scan lighting is the best option. It provides uniform illumination over a wide FoV, allowing the camera to capture high-quality images in a single shot.

- For high-speed inspections of moving objects, line scan lighting is the preferred choice. This method enables precise, high-resolution image acquisition by capturing one line at a time, making it suitable for industries requiring continuous inspection.

CONCLUSION

Both line scan and area scan lighting offer distinct advantages tailored to different automation applications. The choice of lighting depends on the specific inspection requirements:

- Area scan lighting excels in static environments, providing even illumination across a large FoV for high-quality imaging.

- Line scan lighting is ideal for high-speed applications, capturing detailed images of continuously moving objects.

By selecting the right machine vision lighting solution, manufacturers can achieve faster, more accurate inspections, optimize production efficiency, and enhance overall quality control in industrial automation.

Related products

-

Essential ELINE Collimated

- Modular line scan light

- Sizes up to 2500mm

- Passive Cooling

-

Essential ELINE Backlight

- Modular backlight line scan light

- Sizes up to 2500mm

- Passive Cooling

-

Essential ELINE Focused

- Modular focused line scan light

- Sizes up to 2500mm

- Passive Cooling

-

Modular M-HPRING

- Versatile 76 mm ring light

- CW and Strobe OverDrive

- Angle Changer compatible

-

Modular M-TRING

- Powerful 37 mm ring light

- Direct attachment to C-mount lenses

- Angle Changer compatible

-

Modular M-EBAR

- Modular bar light

- Angle Changers flexibility

- Sizes up to 500mm

-

High Power HPBACK

- Powerful homogeneous backlight

- Custom sizes to nearest centimetre

- Sizes from 0.04m² to 0.81m²

-

Essential EBAR+

- High performance bar light

- Angle Changers flexibility

- Sizes up to 2500mm